In 2025, bike frame building can cost anywhere from $200 to over $3,000. The price varies based on the materials, labor, and parts you select. Many people prefer a custom bike frame because it fits them perfectly. Custom frames feel more comfortable and help you ride stronger compared to standard bikes. Skilled builders focus on bike frame building by carefully choosing each part to match your needs and preferences. Creating a custom bike allows you to control both the price and the design, resulting in a bike that will last for years.

Key Takeaways

Making a custom bike frame in 2025 can cost from $1,300 to over $3,000. The price changes based on materials, work, and parts. Picking the right frame material is important. You can choose steel, aluminum, titanium, or carbon. This choice changes the bike’s price, how it rides, and how long it lasts. Custom designs and special paint jobs cost more money. They also make the bike fit better and look cooler. Paying for expert work makes the bike safer and better. Doing it yourself saves money but takes skill and time. It is smart to plan your budget. Spend more on important parts like wheels, brakes, and fitting. This helps you get the best bike for your money.

Price Overview

Total Cost Range

Bike frame building in 2025 can cost a lot or a little. The frame price starts at $200 and can go over $1,000. Labor for putting the bike together adds $450 to $600. When you add parts and finishing, the total is often $1,300 to $3,000 or more. Some top builds with new technology and fancy materials can cost over $4,000. Mountain bikes usually cost more if you pick special suspension or better wheels.

Tip: Riders should make a budget before they start bike frame building. This helps them pick the right parts and not spend too much.

Key Influences

Many things change the final price of a custom bike frame. The biggest things are material, labor, and parts.

Steel is strong and easy to fix. It costs a medium amount.

Titanium is light and does not rust. It costs more because it lasts long and feels fancy.

Carbon fiber is very light and works well. It is the most costly and can break easily.

Aluminum is light and stiff. It is cheaper for most people.

Labor Impact:

Skilled workers build custom bike frames. They use careful planning and special skills.

Making steel by hand or shaping carbon takes more time and money than factory bikes.

Component Choices:

Fancy parts like electronic shifting, carbon wheels, and power meters cost a lot.

If you want fast parts or smart tech, the price goes up.

Mountain bikes cost more with special forks, dropper posts, and tubeless tires.

Problems with getting supplies, like not enough raw materials or shipping delays, have made carbon fiber cost more. Changes in money value and taxes on parts from other countries also raise prices. These things mean that outside problems, not just materials and labor, change the final price in 2025.

Build Type | Frame Price | Labor Price | Total Build Price | Lead Time (Weeks) |

|---|---|---|---|---|

Basic Custom Frame | $200–$1,000 | $450–$600 | $1,300–$3,000+ | 3–7 |

Premium Custom Build | $4,000–$10,000 | $600+ | $4,000–$10,000+ | 9–16 |

Pre-Built Bike | $800–$2,500 | Included | $800–$2,500 | 1–4 |

Custom vs. Pre-Built Bike Costs

Custom bikes usually cost more than pre-built bikes. Companies that make pre-built bikes buy lots of parts at once. This makes each bike cheaper. People who do bike frame building buy one part at a time. These parts cost more because they do not get big discounts. Some parts are only sold to companies, so custom bikes cost more. Custom bikes also need extra work and special tools. Some riders have built bikes for less money by finding deals, but this does not happen often. Most people pay more for custom bikes because of how the market works.

Mountain bikes show the same pattern. Custom mountain bikes with special suspension and top parts cost much more than regular ones. Riders who want special shapes or cool paint should plan to pay more.

Frame Materials

Steel, Aluminum, Titanium, Carbon

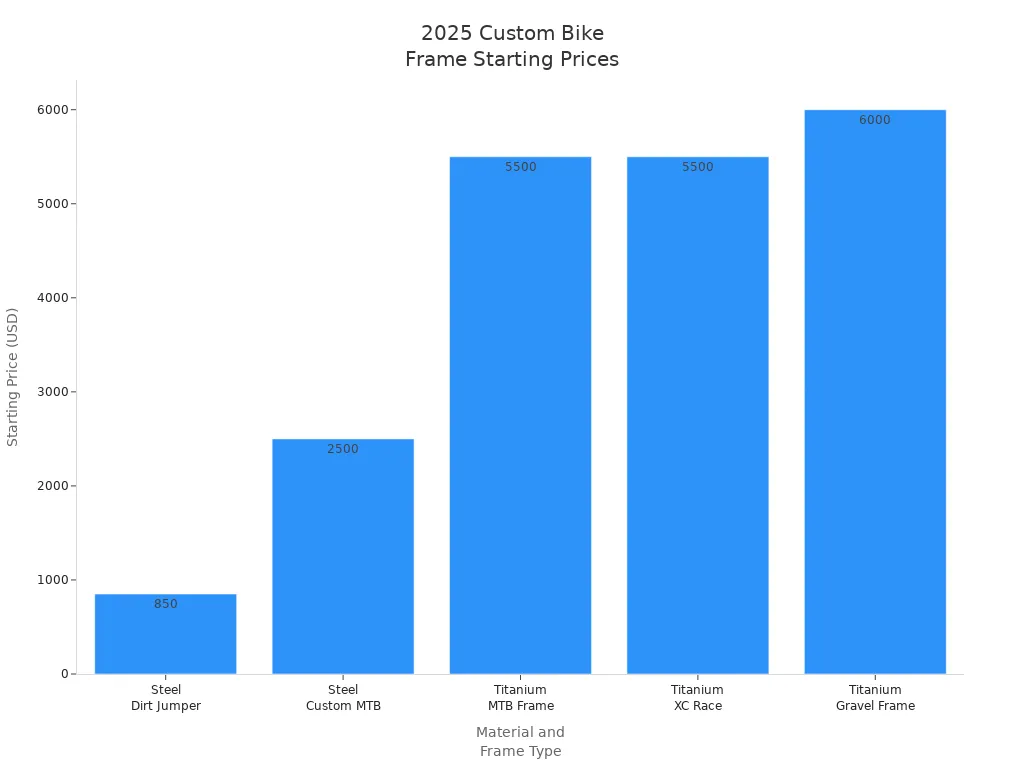

Picking a frame material changes how the bike rides and looks. It also changes the price. In 2025, steel frames are still liked by riders. They give comfort and good value. Aluminum frames are light and stiff. They cost a medium amount. Titanium frames are smooth and last a long time. They cost a lot more than steel or aluminum. Carbon frames are the best for performance. They are the lightest and most expensive.

Material | Typical 2025 Price Range (USD) | Ride Quality & Notes |

|---|---|---|

Steel | Comfortable, lively ride; easy to repair | |

Aluminum | $1,000–$2,500+ | Light, stiff, fast; can feel harsh |

Titanium | $5,500–$6,000+ | Smooth, durable, corrosion-resistant |

Carbon | $1,500–$3,600+ | Lightest, tunable stiffness, premium performance |

Carbon fiber frames are strong and light. They can be shaped in cool ways. Aluminum frames are good for city bikes. They are also used for beginner bikes. These frames balance cost and how well they work. Steel frames feel classic and are easy to fix. Titanium frames last many years and do not rust. Their high price makes them fancy.

Geometry and Design

Custom shapes and designs make frames cost more. Builders change the frame to fit your body. This takes extra time and skill. If you want special shapes or paint, it costs more. Extra work like special brake mounts or cable spots also raises the price.

Note: Custom shapes and paint make each bike special. Builders need more time for these jobs. This makes the price go up. Many riders think the better fit is worth the extra money.

The material you pick changes how the bike feels and what you pay. Steel is comfy and costs less. Aluminum is fast and stiff, but some people think it feels rough. Titanium is smooth and strong, but costs a lot. Carbon is the lightest and gives the best ride. It costs the most and is hard to fix if broken.

Fork and Cockpit

Fork Options

The fork plays a key role in a bike’s performance and comfort. Riders choose forks based on the type of riding they plan to do. In 2025, custom bike builders offer a wide range of fork options. Some brands, like Esker Cycles, provide several Rockshox fork upgrades for their Hayduke Frame. These include models such as the Rockshox PIKE Select and Rockshox SID Ultimate. Each fork features 120mm travel and a 44mm offset, which suits both trail and cross-country riding. CIRCA Cycles includes a tapered fork and headset with their custom frames, starting at $2,300 for the complete package.

Fork prices vary by model and intended use. Road forks, gravel forks, and commuter forks each have different price points. The table below shows typical 2025 price ranges for popular fork models:

Fork Model | Price Range (USD) |

|---|---|

Road X 1″ | $390.50 – $523.45 |

Road X 1 1/8″ | $456.50 – $589.45 |

Gravel X Disc 1.5″ | $583.00 – $673.95 |

Duo 2 Disc 1 1/8″ | $632.50 – $688.45 |

Zephyr 1″ | $390.50 – $523.45 |

Team X Disc 1 1/8″ | $566.50 – $699.45 |

Commuter 1 1/8″ | $622.45 – $699.45 |

A high-quality fork improves steering and absorbs bumps. Riders who want the best performance often select forks with advanced features, such as carbon construction or adjustable damping.

Handlebars, Stem, Seatpost

The cockpit includes the handlebars, stem, and seatpost. These parts affect how the bike feels and fits. Riders can choose flat bars for control or drop bars for speed. The stem connects the handlebars to the fork and sets the reach. A longer stem stretches the rider forward, while a shorter stem creates a more upright position.

Seatposts come in different materials and shapes. Carbon seatposts reduce vibration and add comfort. Aluminum seatposts cost less and offer solid performance. Some riders pick dropper seatposts for mountain bikes. These allow quick height changes on rough trails.

Tip: Riders should test different cockpit setups before making a final choice. A good fit helps prevent pain and boosts confidence on every ride.

Choosing the right fork and cockpit parts ensures the custom bike matches the rider’s needs and style. Each decision shapes the final ride quality and overall cost.

Component Breakdown

Groupset

A groupset has the main moving parts of a bike. These parts help you shift gears and stop. Riders can pick cheap or expensive groupsets. Shimano, SRAM, and Campagnolo are popular brands. Mechanical groupsets cost less and work for most people. Electronic groupsets shift faster and need less work. They cost more and need to be charged.

A good groupset makes the bike ride better. It helps you shift smoothly and stop quickly. Riders who want the best pick electronic or wireless groupsets. These special systems make the bike cost more. Each part in the groupset, like derailleurs, shifters, and brakes, changes the final price.

Wheelset and Tires

Wheelsets and tires are important for the bike’s cost. Rims, hubs, spokes, and materials change the price and how the bike rides. Carbon rims can start at $310 and go up to $2,000. The type of bike decides rim size and width. This changes which tires fit and how the bike feels.

Carbon and titanium make wheels light and strong. These materials cost more but last longer. Custom things like rim shape, hub style, and brake type also add to the price. Riders can build wheels or pay someone to do it. Tire choice is important too. Tubeless rims and special tires cost more. Every part of the wheelset changes how the bike works and what it costs.

Note: Picking the right wheels and tires helps the bike fit the rider and gives a better ride.

Accessories

Accessories finish the custom bike. Common ones are pedals, bottle cages, lights, and fenders. Each one adds to the total price. Riders might also get GPS computers, power meters, or special saddles. These things make riding safer, more comfy, and better.

Good accessories help a lot when you ride every day. Riders should pick what fits their style. Some like light carbon bottle cages. Others want strong racks for carrying things. Each accessory helps make the bike right for the rider.

Labor and Assembly

Professional vs. DIY

Building a custom bike frame takes many steps. Some people pay a pro to build their bike. Others want to do it themselves. Pros use special tools and have lots of experience. They check their work to make sure it is safe. Their bikes meet high standards and work well.

Professional builds cost more because of labor. These costs pay for skilled workers, engineers, and managers. The table below shows the main labor costs for 2025:

Labor Cost Component | Estimated Cost Range | Description |

|---|---|---|

Production Workforce Salaries | $40,000 – $150,000 | Wages for skilled production workers and line managers responsible for assembly and production tasks |

Engineering & Management | $20,000 – $70,000 | Salaries for engineers and management overseeing design and production processes |

Payroll Taxes, Benefits & Training | $20,000 – $30,000 | Includes workers’ compensation, insurance, and training expenses necessary for skilled labor |

Doing it yourself can save money. But it takes time and patience. You need some skill with tools. Many people like learning about their bike this way. DIY builds may not be as perfect as pro builds. There is no set cost for DIY labor. Riders must guess the cost by adding up their time and tool prices.

Tip: Try small projects first if you want to build your own bike.

Fitting Services

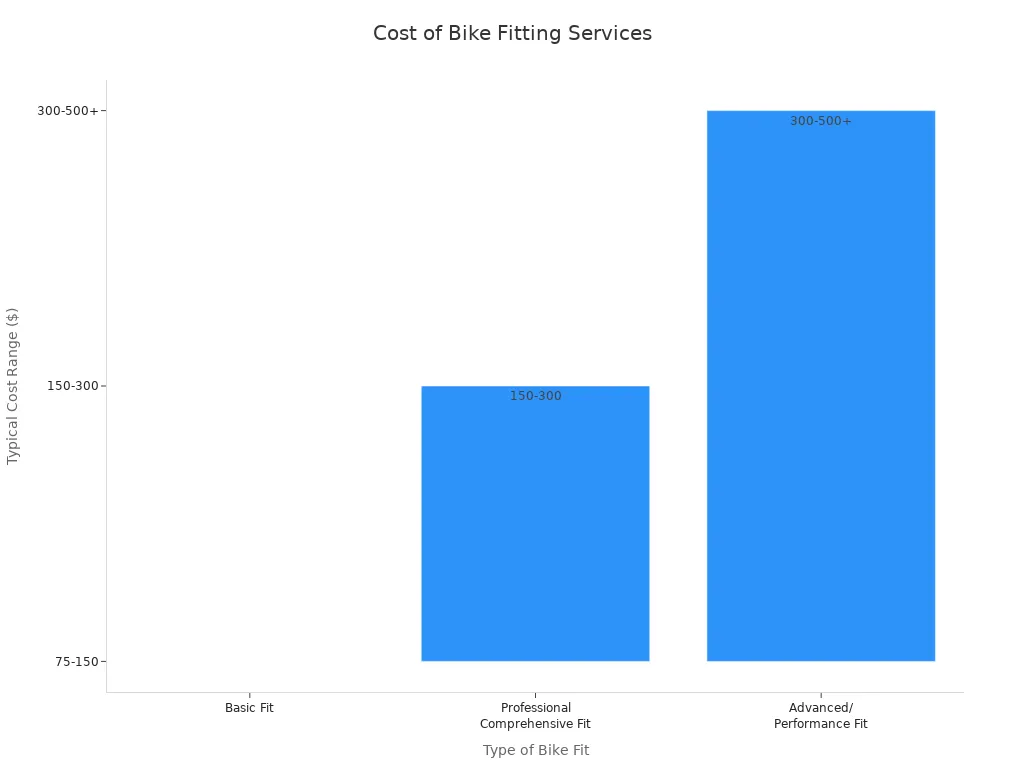

Fitting services help riders feel good on their bikes. A good fit stops pain and helps you ride better. There are different levels of fitting. Some are simple, and some use high-tech tools. Each level adds to the total price.

Type of Bike Fit | Description | Ideal For | Pros | Cons | Typical Cost Range |

|---|---|---|---|---|---|

Basic Fit | Adjustments to saddle height, handlebar position, and cleat alignment | Casual riders or those needing simple adjustments | Affordable and covers essential adjustments | Limited scope | $75 – $150 |

Professional Comprehensive Fit | Detailed assessment including body measurements, motion analysis, and real-time feedback | Frequent cyclists aiming for comfort and performance | Highly personalized, uses advanced tools like video motion capture | More expensive | $150 – $300 |

Advanced/Performance Fit | Uses high-tech tools such as 3D motion capture, pressure mapping, and dynamic fitting systems | Competitive cyclists and athletes | Highest precision, performance benefits, custom equipment recommendations | Most expensive | $300 – $500+ |

Fitting services cost between $75 and $500 or more. Experts use special tools and their knowledge to help. They make sure the bike fits your body and how you ride. Many people think this is a smart way to spend money for comfort and better rides.

Sourcing Parts

Local vs. Online

In 2025, riders can get parts two ways. They can buy from local shops or order online. Local bike shops give advice and help with fitting. They also help after you buy the parts. Many riders like to see and touch parts first. Local shops sometimes give discounts for buying more or being loyal.

Online stores have more brands and rare parts. You can compare prices fast and find special items. But online orders may have shipping fees and take longer to arrive. Some online sellers charge more for assembly or special boxes.

Sourcing Method | Typical Cost | Customization | Extra Fees | Convenience |

|---|---|---|---|---|

Local Shop | Lower | Moderate | Fewer (no shipping) | High |

Online | Higher | High | Shipping, assembly | Moderate |

Tip: Riders who want to save money often pick local shops. Riders who want rare parts may shop online, even if it costs more.

Import Costs

Import costs and taxes change the final price of bike parts in 2025. These costs include tariffs, VAT, import duties, and other fees. Some trade deals make costs lower, but others make them higher.

US tariffs on Chinese bike parts are still high, sometimes over 100%.

The US took away the duty-free rule for Chinese goods, so all pay tariffs.

Bicycles have an 11% customs duty in the US. Other parts have 3.9% to 10%.

Some Chinese goods get a 125% duty, plus extra tariffs like Section 301.

The EU–Vietnam Free Trade Agreement removes customs duties for Vietnamese frames.

The UK adds VAT and import duties after Brexit, making things harder.

The EU uses anti-dumping duties on Chinese frames, so companies look elsewhere.

Trade deals in Asia, like RCEP, lower tariffs for local suppliers.

Environmental and safety rules add more costs.

Some governments give help for local production, but import costs still matter.

Import costs can change fast. Riders should check the latest rules before buying parts from other countries. These costs can make a big difference in the total price of a custom bike build.

Budgeting for Building a Custom Bike

Where to Save

Smart riders know you do not have to spend the most. There are ways to save money when building a custom bike. Here are some tips:

Wait for sales or shop online during big discounts. Prices drop at the end of the year or on special days.

Buy used or new-in-box parts from other people. This is cheaper than buying brand new parts at stores.

Start with just a frame and pick each part yourself. This helps you find the best deals for every piece.

Move parts from one frame to another over time. This saves money instead of buying many full bikes.

Pick fancy drivetrains but use cheaper brakes, wheels, or suspension. This keeps the bike fast but costs less.

Watch for price changes in your area and wait for good deals. Knowing the market helps you save money.

Some riders say they built a custom bike for half the price of a full bike from a company by using discounts and smart choices.

Tip: Cheap or used parts can sell out fast. Sometimes, a full bike with good parts is the best deal.

Where to Invest

Some parts and services are worth spending more on. Riders should focus their money on these things:

Carbon wheelsets, disc brakes, and tubeless setups make the ride better and safer.

Make sure all parts, like cassettes and shifting systems, fit together.

Let a pro put your bike together, especially if you buy parts online.

Bike fitting services help you feel good and stop pain.

If you build your own bike, check it for safety.

Good cranks, handlebars, saddles, and wheels last longer and work better.

Some brands sell carbon frames straight to buyers for a good price.

Spending more on these things saves money later and makes riding more fun. Riders who take their time and pay attention have fewer problems and enjoy their bikes more.

Value of Custom Bike Frame Building

Fit and Performance

Custom bike frames help riders get a better fit. Standard frames can be changed a little, but custom frames fit your body and style exactly. Experts measure things like your legs and torso. They also check how flexible you are. This helps them design a frame that gives comfort and power. Riders sit in the best spot, so they do not need to move handlebars or seatposts a lot. This stops pain and helps you ride better for a long time.

Custom geometry puts your body in the right place. This helps your muscles work well and makes it easier to breathe. For example, a custom aero frame might have a steeper seat tube and a shorter top tube. This keeps your hips open and your arms in a good spot for speed. You can hold strong positions longer and cut down on wind drag. You can also control the bike better. Studies show a custom frame can lower drag by up to 20%. This makes each pedal stroke work better. New tools like 3D printing help builders make frames that fit every detail you need.

A custom bike frame lets riders be comfortable, strong, and efficient.

Aesthetics and Personalization

A custom bike frame looks special and shows off your style. Many builders offer cool paint, finishes, and details. These things let you pick what matches your personality. People want bikes that feel unique and look great. Brands like Firefly Bicycles use fancy finishes, like anodization, to stand out and get noticed.

Custom builders make their bikes one-of-a-kind.

Riders like to share pictures of their custom bikes with others.

Brands use words like “built for you” to show how special each bike is.

Custom color-matched accessories, like frame bags, make the bike look even better.

Shops that show how they build bikes and tell their story earn trust.

The Framework bike review says custom frames are built with care and look amazing. These things make the bike more wanted and make riders happier. Riders see their custom bike as something to keep for a long time, not just for riding. The value comes from how it rides and how it shows who you are.

Building a custom bike in 2025 costs money for many reasons. The table below shows the main things that change the price:

Cost Driver | Description |

|---|---|

Materials | |

Skilled Labor | Special work and new tools make prices go up. |

Facility and Utilities | Making bikes needs space and power, which adds cost. |

Customization | Cool designs and smart features need extra money. |

To save money and get what you want, riders should:

Make a budget and plan when to finish.

Pick frame material and style for how you ride.

Expert builders say to plan well, check if parts work together, and ask for help before you start. If you want a bike that works well and is easy, a pre-built bike is often a better deal. This is true for people who ride every day or are buying their first bike.

FAQ

How long does it take to build a custom bike frame in 2025?

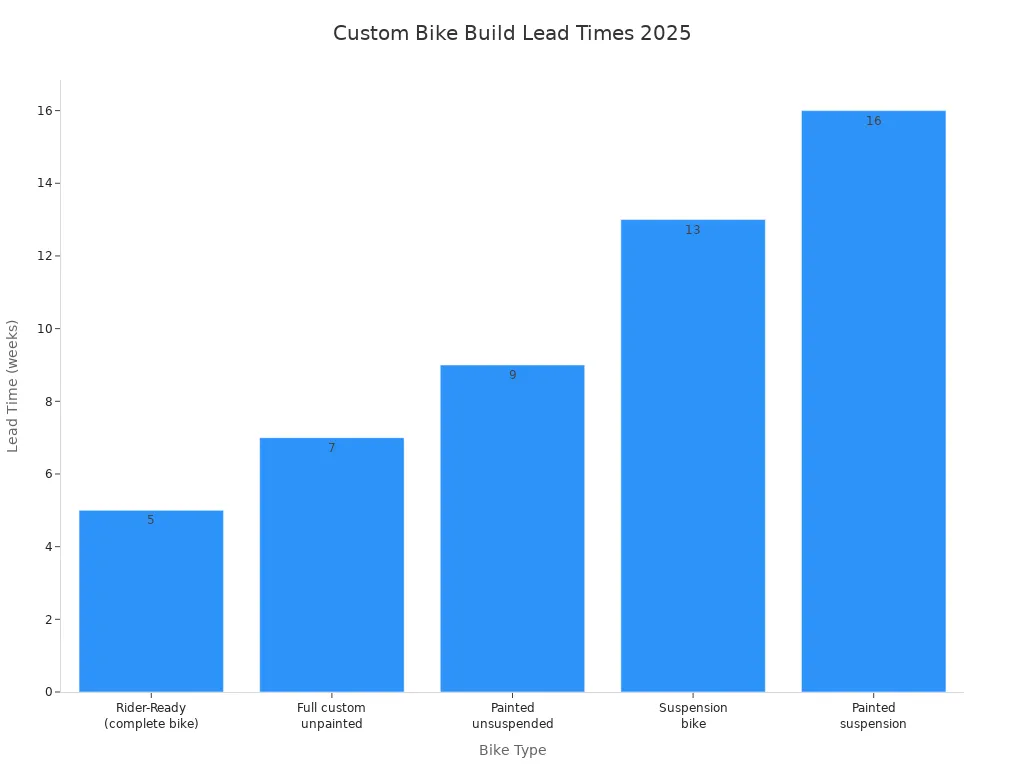

Most builders need 3 to 16 weeks to finish a custom frame. The time depends on the material, design, and how busy the builder is. Special builds with extra features can take even longer. Riders should always ask for a timeline before they order.

What is the best frame material for beginners?

Steel is comfy, strong, and easy to fix. Many new riders pick steel because it rides smooth and costs less. Aluminum is good for people who want a lighter bike. Titanium and carbon are better for advanced riders who want the best performance.

Can riders use old bike parts for a new custom frame?

Yes, many builders let riders use old parts like wheels, handlebars, and saddles. It is important to check if the old parts fit the new frame. Riders should ask the builder to make sure everything works together. This helps save money and cuts down on waste.

Do custom frames come with a warranty?

Most good builders give a warranty for custom frames. The coverage changes by brand and material. Riders should read the warranty rules before they buy. Some warranties cover problems with the frame, and some also help if you crash.

See Also

Discovering How Carbon Fiber Bike Frames Are Made

A Buyer’s Guide To Carbon Aluminum And Steel Frames

Top Ten Custom Bike Frame Ideas To Inspire Creativity