Bike frame analysis is very important for safety and performance. Engineers and designers use different methods to check how strong bike frames are. One of these methods is Finite Element Analysis (FEA). FEA can simulate tough conditions that bikes face. This method uses different parts, like truss and beam, to predict stress and bending. Experimental techniques work with FEA. They give proof and detailed data about strain. Together, these methods help improve materials and design. This makes the cycling experience better overall.

Key Takeaways

Finite Element Analysis (FEA) helps engineers see how strong bike frames are. It does this by simulating forces and stresses on detailed models.

Static testing checks bike frames with heavy loads. This ensures safety and durability for everyday use.

Dynamic testing simulates real-life riding conditions. It includes bumps and impacts to predict frame fatigue and improve comfort.

Modal analysis studies bike frame vibrations. This helps prevent resonance and improves ride quality and frame durability.

Using these methods together makes bike frames safer, stronger, and better. They meet modern standards.

Finite Element Analysis

Methodology

Finite Element Analysis (FEA) is very important for bike frame analysis. This method helps engineers see how bike frames react to different forces. The process has several key steps:

Model Construction: Engineers build a complete finite element model of the bike frame shape. This includes details like tube lengths, connections, and tubing types.

Element Subdivision: The frame splits into finite elements, usually beam elements. Each element gets mechanical properties like cross-sectional area and moments of inertia.

Material Specification: Engineers define material properties, including elastic modulus, shear modulus, Poisson ratio, and mass density.

Loading Conditions: Different loading conditions and boundary limits are applied to mimic real-world forces on the frame.

Equation Solving: The system of equations is solved to find node movements and internal stresses in the frame elements.

Result Analysis: Engineers look at the results to find critical loading conditions, stress points, and deflections.

Design Optimization: The analysis results help improve frame design for strength, stiffness, and performance, ensuring safety standards are met.

Iterative Design: Engineers may change the shape or material properties and run the analysis again to enhance frame features.

This simulation-based engineering method improves the accuracy of stress and strain predictions in bike frames. By modeling the whole bike structure with elastic elements, FEA shows the real behavior of parts like the frame and rider weight.

Advantages

The benefits of using finite element analysis over traditional methods are clear:

Complex Geometries: FEA can manage complex shapes, while traditional methods often stick to simpler forms.

Nonlinear Properties: FEA can handle nonlinear material properties, unlike traditional methods that assume consistent properties.

Realistic Conditions: FEA supports real-world boundary conditions and loading situations, like changing loads and dynamic forces.

Virtual Testing: This method allows for virtual testing and optimization before making physical prototypes, saving time and money.

Speed and Intuition: FEA simulations are usually faster and easier to understand than lengthy traditional calculations.

Scalability: FEA can adapt to different sizes, materials, or conditions, making it useful for various designs.

Multi-Physics Problems: FEA can deal with multi-physics problems involving many interacting factors, unlike traditional methods that focus on one aspect.

These benefits make FEA a popular choice for bike frame analysis, allowing for more accurate predictions and better design choices.

Applications

Finite element analysis has many uses in bike frame design. Engineers use FEA to:

Optimize Designs: FEA helps improve frame shape and material use, leading to better performance and safety.

Conduct Case Studies: Important case studies show how FEA led to big improvements in bike frame performance. For example, one study improved a titanium bike frame design for strength and durability. The analysis found critical stress points and confirmed results with physical prototypes.

Predict Structural Behavior: FEA predicts how composite bicycle frames will behave, helping designers make smart choices about materials and design features.

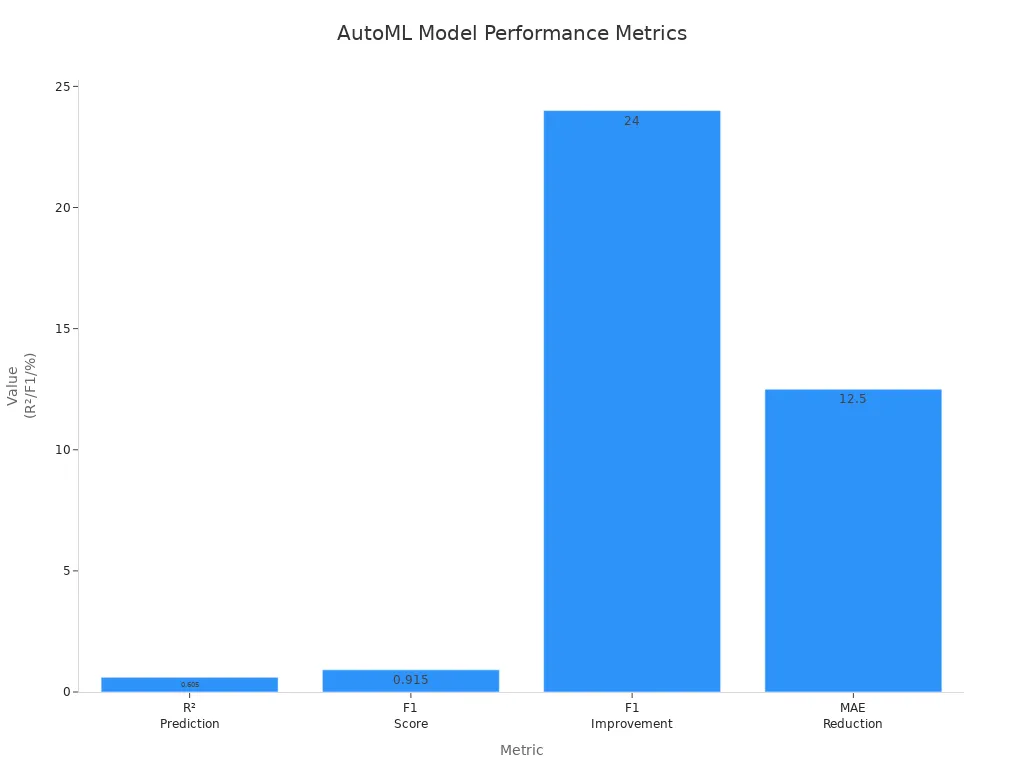

Software like SimScale makes these analyses easier by providing cloud-based FEA tools. This software supports various structural mechanics analyses, making it available for engineers without needing expensive hardware.

Static Testing

Methodology

Static testing checks how strong and durable bike frames are. The steps usually include:

Decide the age group and market for the bike.

Prepare a complete bike for testing.

Add documents like user manuals and labels.

Test the strength and fatigue of parts, including the frame, by adding loads that mimic rider weight.

Use numerical methods like Finite Element Method (FEM) to analyze stress and safety factors. This helps predict performance and meet standards like ISO 4210 and CPSC rules.

Check labels and follow local rules during testing.

In static testing, engineers add loads that match a rider’s weight, usually about 100 kg. This helps find the highest stress values and safety factors for different frame designs. By using methods like FEM, manufacturers can confirm the frame’s strength and safety without costly tests.

Advantages

Static testing has many important benefits for checking bike frame durability:

It slowly adds heavy loads to find any yielding or permanent bending.

The test shows if the frame can stay strong under heavy loads, ensuring safety and long life.

It checks if the frame can take hits without cracking or bending.

Static tests give a safety margin beyond normal use by mimicking real-life heavy loads.

This method works well with fatigue and dynamic tests by focusing on how the frame reacts to heavy loads.

It helps meet standards like EN 17860 and DIN 79010, proving the frame’s durability.

Overall, static testing makes sure the frame won’t fail badly under heavy or unusual loads, making it safe for daily use.

Static testing is also very important for safety certification. It puts a load on the bike frame for a short time to check its strength under expected stress. This test is part of many safety checks that ensure the frame can handle loads beyond regular use.

Applications

Static testing is key for many uses in bike frame analysis. Engineers often study materials like aluminum alloy because it is strong, light, and affordable. Studies show that aluminum alloy frames have small deformations and absorb vibrations well under normal rider loads. Important material properties, like Young’s modulus (69 GPa) and yield strength (280 MPa), are key factors in these studies.

Static testing also uses lab machines like universal tensile test machines for checking static loads. Measurement methods include linear static structural finite element analysis (FEA) to predict stress and deformation. These techniques help ensure the reliability and accuracy of testing prototypes.

Dynamic Testing

Methodology

Dynamic testing checks how bike frames work in real life. This method has several important steps:

Define Material Properties: Engineers list properties like elastic modulus, Poisson’s ratio, density, and yield strength for the bike frame materials.

Create a 3D Model: A detailed 3D model of the bike frame is made to show its structure correctly.

Generate a Mesh: The frame is split into small pieces, with a finer mesh around high-stress spots like welds and joints.

Apply Realistic Loads: Engineers add static loads, like rider weight, and dynamic loads that mimic bumps or impacts on the road.

Run Simulations: Simulations check stress (Von Mises), strain, and movement to see how the frame performs.

Interpret Results: Engineers find peak stress, stress hotspots, and safety factors from the simulation data.

Predict Fatigue Life: Tools predict how long the frame will last under repeated loads.

Design Improvements: Based on results, engineers strengthen weak areas or change tube thickness to improve performance.

Dynamic testing shows the challenges of real cycling. It simulates different dynamic loads, including vertical and horizontal forces, to copy what bicycles face during use.

Advantages

Dynamic testing has many benefits over static testing:

Realistic Conditions: It shows real-life conditions like frequency response, damping, and comfort factors.

Comprehensive Assessment: Dynamic tests check efficiency, comfort, and energy transfer during actual use.

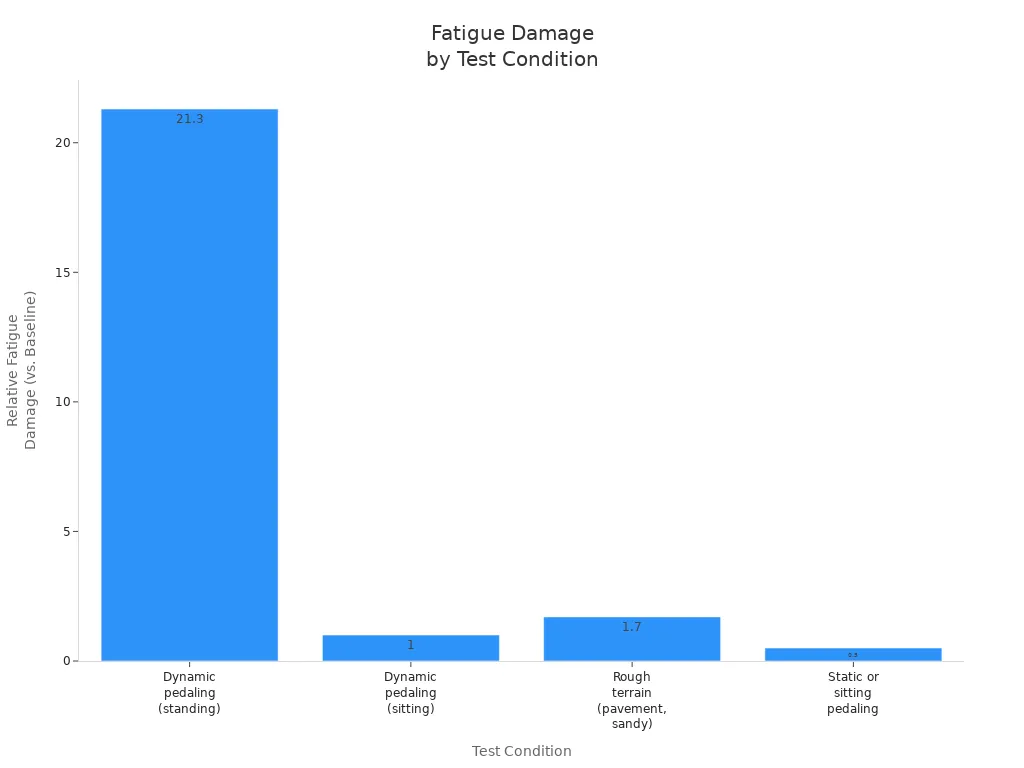

Fatigue Life Prediction: This method helps guess how long bike frames will last by simulating real-world loads, like bumps and impacts.

Identifying Performance Issues: Dynamic testing can find problems that static testing might miss. For example, one study found that dynamic tests showed increased resistance in a gantry drive frame that static tests did not find.

Dynamic testing also measures human energy use and torque under load. This gives insights into real-world performance that static tests cannot fully show.

Applications

Dynamic testing has many uses in bike frame analysis:

Simulating Real-World Conditions: Engineers use fixed points and rotational limits to copy real bike movement. Static loads show the rider’s weight, while dynamic loads mimic impacts from road bumps.

Assessing Frame Durability: Tests include side-to-side forces, impact tests, and jump fatigue tests. These tests help see how frames handle stress from hard pedaling and turning.

Optimizing Design: Results from dynamic testing guide design changes, like adding support ribs or making tubes thicker, to improve frame durability.

Dynamic testing gives a strong basis for estimating fatigue life and guiding design changes. By simulating real-world conditions, engineers can make sure bike frames work safely and reliably.

Modal Analysis

Methodology

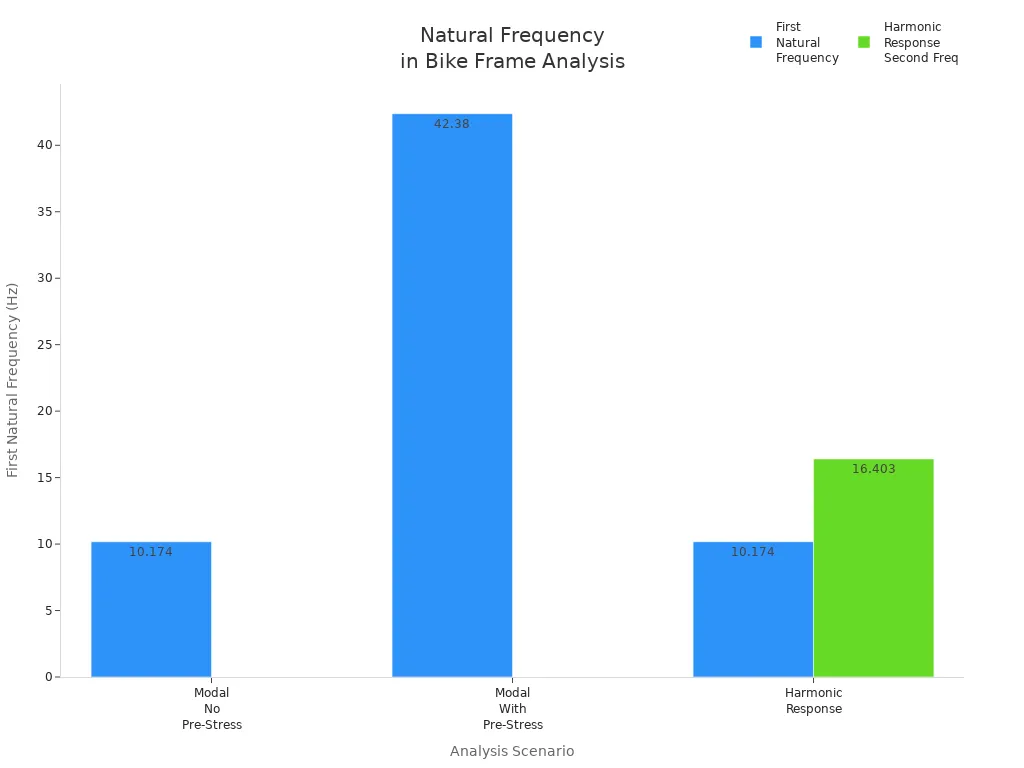

Modal analysis is very important for understanding how bike frames vibrate. This process has several key steps:

Excitation: Engineers use impact hammers or shakers to make the bike frame vibrate.

Data Collection: They measure vibrations at different points on the frame with sensors like tri-axial accelerometers.

Parameter Identification: Engineers analyze the data to find modal parameters, like natural frequencies, mode shapes, and damping characteristics.

Finite Element Model Creation: A detailed finite element (FE) model of the bike frame is made using CAD software, like CatiaV5.

Meshing and Analysis: The FE model is divided into smaller parts with tools like Hypermesh and analyzed using FE solvers like ANSYS or LS-DYNA.

Boundary Conditions: Engineers set boundary conditions that mimic real-world limits, like steering and suspension joints.

Numerical Modal Analysis: They perform numerical modal analysis to find natural frequencies and mode shapes.

Validation: Finally, they check the numerical results against experimental data to make sure they are correct.

This combined method helps find bending and twisting modes, improve frame design, and prevent resonance.

Advantages

Modal analysis has many benefits in bike frame engineering:

It finds natural frequencies, mode shapes, and damping characteristics, which are important for understanding vibrations.

Engineers can reduce vibration effects, stopping problems from small annoyances to serious failures.

This analysis checks finite element models with experimental data, ensuring simulations are accurate.

It helps improve frame strength, stiffness, and weight by guiding design changes.

Modal analysis prevents resonance by making sure frame resonance frequencies do not match the frequencies from moving parts.

It gives a complete picture of dynamic properties, leading to better design, durability, and performance of bike frames.

Applications

Modal analysis is important in many situations for bike frame design. It helps calculate internal forces during critical times, like maximum acceleration and braking. The results help with deformation and safety factor calculations, making sure the design meets performance and customer needs. Also, modal analysis helps reduce noise and improve ride comfort by studying how suspensions handle road bumps. This knowledge leads to better designs that enhance the overall cycling experience.

Bike frame structural analysis is very important for safety and performance. Engineers use methods like Finite Element Analysis, Static Testing, Dynamic Testing, and Modal Analysis to improve designs and predict how frames behave in different situations. New research highlights the use of advanced software tools, like RSTAB 9 and RFEM 6, which make modeling more accurate and help meet international standards.

Current Trends:

Digital manufacturing allows for custom bike frames.

Smart technologies improve real-time diagnostics and rider interaction.

Sustainability encourages using recycled materials for frames.

These improvements are changing the future of bike frame design. They help manufacturers meet changing consumer needs while focusing on safety and performance.

FAQ

What is Finite Element Analysis (FEA)?

FEA is a computer method that engineers use. It helps predict how bike frames react to different forces. The frame is split into smaller parts. This allows for detailed checking of stress and strain.

Why is static testing important for bike frames?

Static testing checks how strong and durable bike frames are. It uses controlled loads to see if frames can handle real-world conditions. This method makes sure frames meet safety standards.

How does dynamic testing differ from static testing?

Dynamic testing looks at bike frame performance in real life. It simulates impacts and vibrations. Static testing, on the other hand, focuses on how the frame reacts to steady loads.

What role does modal analysis play in bike frame design?

Modal analysis finds out how bike frames vibrate. This helps engineers understand how frames react to moving forces. It improves the design and performance of the frames.

Which materials are commonly tested in bike frame analysis?

Engineers often test materials like aluminum alloys and carbon fiber. These materials are strong, light, and affordable. They are popular choices for making bike frames.

See Also

Understanding The Mechanics Behind Foldable Bicycle Frames

Learn Simple Methods To Sketch Bicycle Frames Perfectly

The Role Of Science In Fixing Carbon Bike Frames

Key Measurements To Accurately Choose Bike Frame Size

Essential Parts Of Bike Frames And Their Functions Explained