When you look at bike frame tubes, you see five main materials. These are hi-tensile steel, chromoly steel, aluminum, carbon fiber, and titanium. Each material changes how a bike rides and feels. It also affects how long the bike lasts. Many riders choose aluminum frames. Aluminum frames are light and not too expensive. Carbon fiber frames are very stiff and give smooth rides. But carbon fiber frames cost more money. Steel frames are strong and comfortable. But steel frames make the bike heavier. Titanium frames are smooth and last a long time. But titanium frames are much more expensive. You should think about how you ride and your budget. You should also think about what you want from your bike frame.

The table below shows how weight, stiffness, durability, cost, and ride quality are different for each bike frame material:

Factor / Material | Carbon Fiber | Aluminum | Steel | Titanium |

|---|---|---|---|---|

Weight | Very light | Light | Heavy | Light |

Stiffness | High | Moderate | Moderate | Moderate |

Durability | Fragile under impact | Good corrosion resistance, fatigue concerns | Very durable, prone to rust | Excellent fatigue resistance |

Cost | High | Moderate | Low | Very high |

Ride Quality | Stiff, vibration damping | Good balance | Smooth, compliant | Smooth, durable |

Key Takeaways

Bike frames use five main materials. These are aluminum, carbon fiber, steel, titanium, and chromoly steel. Each material changes the bike’s weight, comfort, strength, and price.

Aluminum frames are light and cheap. They do not rust. They are good for new riders and daily rides. But they can feel hard on bumpy roads.

Carbon fiber frames are the lightest. They give very smooth rides. Racers and people who want speed like them. They cost more money. You must check them for damage often.

Steel frames give smooth and comfy rides. They are easy to fix. They are great for long trips and adventures. But they are heavier. They can rust if you do not care for them.

Titanium frames are light and strong. They last a long time and feel good to ride. They are for people who want a tough bike. You need to pay more at first for these bikes.

Aluminum Bike Frame Tubes

Properties

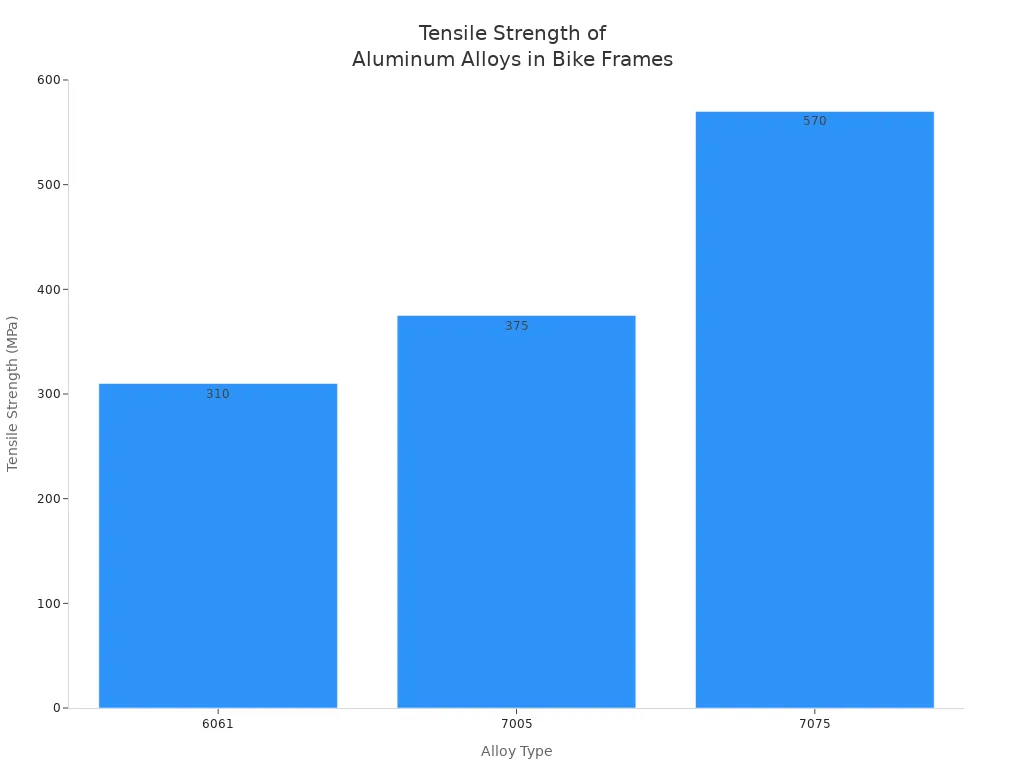

Aluminum is the most used material for bike frames today. It is much lighter than steel. Aluminum’s density is about one-third of steel. This makes bikes feel lighter and easier to move. Aluminum does not rust, so frames last longer. Most frames use alloys like 6061, 7005, or 7075. Each alloy has its own strengths and uses. For example, 6061 is good against rust and is easy to weld. 7075 is stronger but harder to work with.

Alloy | Main Composition | Tensile Strength (MPa) | Corrosion Resistance | Weldability | Machinability | Typical Use |

|---|---|---|---|---|---|---|

6061 | Al + 1% Mg + 0.6% Si | ~310 (T6) | Very Good | Excellent | Good | Versatile bike frames, boats |

7005 | Al + 4.5% Zn + 1.4% Mg | 350–400 (T6) | Decent (needs coating) | Good (no post-weld heat treatment) | Okay | Mountain and road bike frames |

7075 | Al + 5.6% Zn + 2.5% Mg | ~570 (T6) | Moderate (needs coating) | Poor (prone to cracking) | Good | High-performance bike frames, aerospace |

Pros and Cons

Aluminum bike frames have many good points:

They are light, so bikes are easy to ride.

They are stiff, so you feel fast when you pedal.

They do not rust, so they last in wet weather.

They cost less than carbon fiber or titanium.

They can be shaped into many designs.

But there are some downsides:

They do not last as long as steel.

They are hard to fix if broken.

The ride can feel rough on bumpy roads.

Manufacturing

Making an aluminum frame takes a few steps:

Aluminum is made into tubes of different sizes.

The tubes are cut and shaped to fit together.

The tubes are welded, often with TIG welding.

The frame is heat-treated to make it strong again.

The frame is lined up and finished to be smooth.

These steps help keep the price low. New ways like hydroforming make frames even lighter and stronger.

Who It’s For

Pick an aluminum bike frame if you want a light and cheap bike. Aluminum is good for new riders and people who ride to work. It is also good for anyone who wants a fun bike without spending a lot. If you want a very soft ride or go far, you may want another material. For most people, aluminum gives a good mix of price, weight, and how it rides.

Carbon Fiber Bike Frame

Properties

Carbon fiber is a popular choice for fast bikes. It is very light and also very strong. Carbon-fiber composite frames use woven carbon sheets with resin. Changing the fiber direction changes how stiff or soft the frame feels. This lets you get a bike that feels fast and smooth. The table below shows how strong and stiff each carbon fiber type is:

Carbon Fiber Type | Modulus of Elasticity (GPa) | Tensile Strength (MPa) |

|---|---|---|

Low Modulus (LM) | < 100 | > 3000 |

Intermediate Modulus (IM) | 200 – 350 | Up to ~5000 |

High Modulus (HM) | 350 – 450 | > 4500 |

Ultra-High Modulus | Up to 700 | Up to 7000 |

You can have a frame that is very stiff or more bendy. This depends on how the carbon is layered. Carbon fiber frames are special because of this.

Pros and Cons

There are many good things about carbon fiber frames:

They are very light, so bikes are easy to lift.

They are stiff in some spots, so you pedal faster.

The ride feels smooth because carbon soaks up bumps.

Makers can change the frame for comfort or speed.

If you take care of it, the frame can last a long time.

But there are also some bad things:

Carbon fiber frames cost a lot of money.

Cracks can hide after a crash, so check your frame often.

Hard hits can make the frame weaker.

Cheaper carbon frames can be heavier and not last as long.

Tip: Always look over your carbon fiber frame for damage, especially after a fall.

Manufacturing

Making a carbon fiber frame uses a special process. Makers put carbon sheets in different ways to control weight and stiffness. Machines help place the fibers very carefully. This makes the frame strong where it needs to be. Prepreg sheets keep the resin even. Filament winding and AFP help make cool shapes and waste less. Careful work and checking stop mistakes, so you get a strong frame.

Who It’s For

Pick a carbon fiber frame if you want the best performance. High-modulus carbon is great for racers who want the lightest, stiffest bike. Intermediate-modulus carbon is good for people who want comfort on long rides. Standard-modulus carbon works for riders who want good bikes at a lower price. If you want speed, smooth rides, and a bike that feels just right, carbon fiber is a great choice.

Steel Bicycle Frame Tubes

Hi-Tensile vs Chromoly

There are two main steel types for bike frames. One is hi-tensile steel. The other is chromoly steel. Hi-tensile steel is a simple carbon steel. Chromoly steel has chromium and molybdenum in it. These two types are not the same. They have different strengths and weights. They are used for different things.

Aspect | Hi-Ten Steel | Chromoly Steel |

|---|---|---|

Composition | High-tensile steel without chromium or molybdenum | Alloy with chromium and molybdenum |

Strength & Durability | Decent strength, less durable | Stronger, more durable, better fatigue resistance |

Weight & Performance | Heavier, thicker tubes | Lighter, thinner tubes, better strength-to-weight |

Ride Comfort | Stiffer ride, less vibration absorption | Smoother ride, better vibration absorption |

Corrosion Resistance | Needs coatings, less resistant | More corrosion resistant due to chromium |

Manufacturing | Simpler welding, lower cost | Advanced welding, heat treatment, higher cost |

Cost | Budget-friendly | More expensive |

Properties

Steel has been used for bike frames for a long time. Steel tubes are strong and comfortable to ride. Chromoly steel, like 4130, is both strong and bends without breaking. It has a yield strength of 435 MPa. Its fatigue limit is 320 MPa. Other grades, like Reynolds 531 and 853, are even stronger. These tubes can make bikes lighter. Steel tubes can handle rough roads and heavy bags.

Pros and Cons

Steel frames give a smooth and comfy ride. Many people like how steel bikes feel. You can fix steel frames if they break. Steel can be recycled and is often made nearby. But steel frames are heavier than aluminum or carbon. If you do not take care of steel, it can rust.

Pros of Steel Frames | Cons of Steel Frames |

|---|---|

Smooth, comfortable ride | Heavier than other materials |

Long lifespan | Can rust if not maintained |

Easy to repair | |

Good for touring and adventure | |

Environmentally friendly |

Note: Some new steel tubes, like Reynolds 853, are light and strong. Not all steel bikes are heavy.

Manufacturing

Bike makers use different ways to build steel frames. Hi-tensile steel frames use simple welding and thick tubes. Chromoly frames need special welding and heat treatment. They also use butted tubes. Butted tubes are thin in the middle and thick at the ends. This makes the frame lighter but still strong. Chromoly frames take more skill and time to make. They last longer and ride better.

Who It’s For

Steel bike frames are good for many riders. If you want to tour, commute, or go on adventures, steel is a good pick. Chromoly frames are great for BMX, gravel, and long rides. Hi-tensile frames are good for beginners or people who want to save money. Steel frames are comfy and last a long time. They are good for carrying heavy things or riding far. People who build custom bikes also like steel because it is easy to shape.

Titanium Bike Frames

Properties

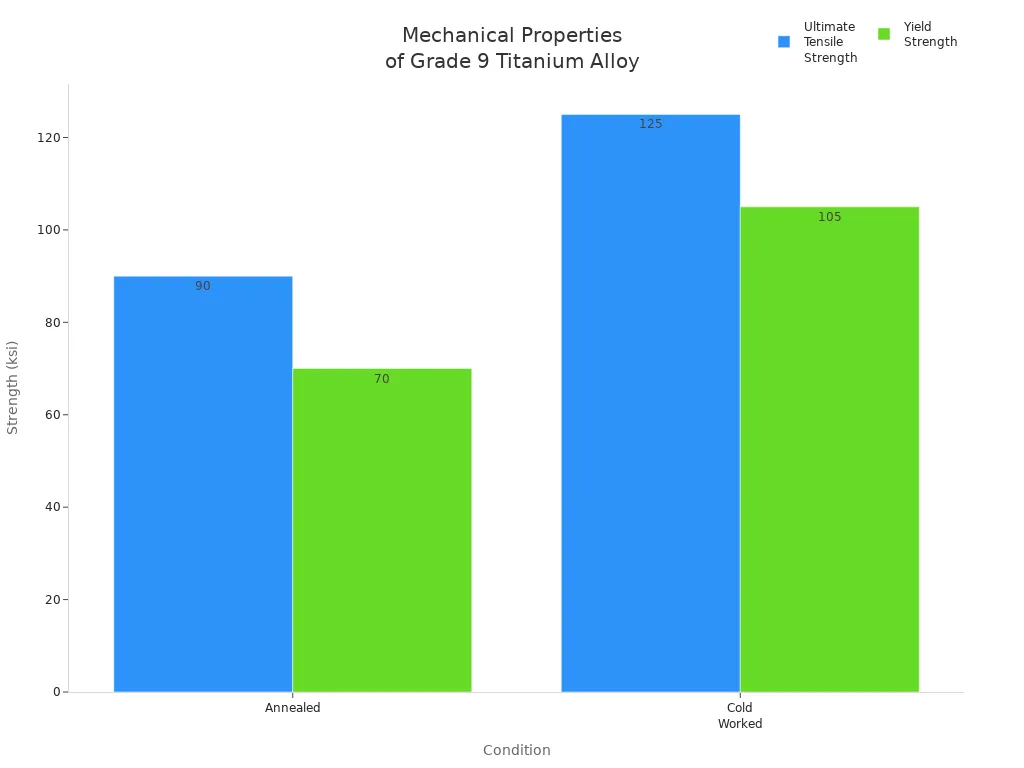

Titanium is a top material for bike frames. It is strong and light. It does not rust or get damaged easily. Grade 9 titanium alloy has 3% aluminum, 2.5% vanadium, and 94.5% titanium. This mix makes the frame very strong and tough. It also helps the frame last a long time. Titanium can soak up bumps, so rides feel smooth. You get both comfort and good performance. Titanium is easy to shape into many frame styles. The table below shows how strong this material is:

Property | Annealed Value | Cold Worked Value |

|---|---|---|

Ultimate Tensile Strength | 125 ksi (862 MPa) | |

Yield Strength | 70 ksi (485 MPa) | 105 ksi (724 MPa) |

Pros and Cons

Titanium bike frames have many good points:

They soak up shocks, so rides feel smooth.

They do not rust, so bikes last a long time.

They handle bumps and rough roads well.

But there are some downsides:

Titanium frames cost more than most others.

Welding titanium needs special tools and skill.

Titanium bike frames cost more at first. But they last a long time and feel great to ride.

Manufacturing

Making a titanium bike frame takes many steps:

Designers plan the frame’s shape and size.

Workers cut and clean the titanium tubes.

Welders join the tubes with special skills and tools.

Machinists put the frame together and check it.

The frame gets painted or finished to look nice.

Experts test the frame to make sure it is strong.

These steps make the frame cost more. But you get a bike that lasts and works well.

Who It’s For

Pick a titanium bike frame if you want comfort and a bike that lasts. Titanium is good for people who ride far or on rough roads. It is great for riders who want a smooth ride for many years. Titanium frames are good for long trips, hard weather, and tough rides. If you want a bike that stays strong and feels good, titanium is a smart pick.

Comparing Bike Frame Tubes

Weight and Strength

When you look at bike frame tubes, weight and strength matter a lot. You want a bicycle that feels light but stays strong. Different materials change how heavy your bike feels and how much force it can handle. Carbon gives you the lightest frames. Aluminum and titanium are close in weight. Steel makes the heaviest frames.

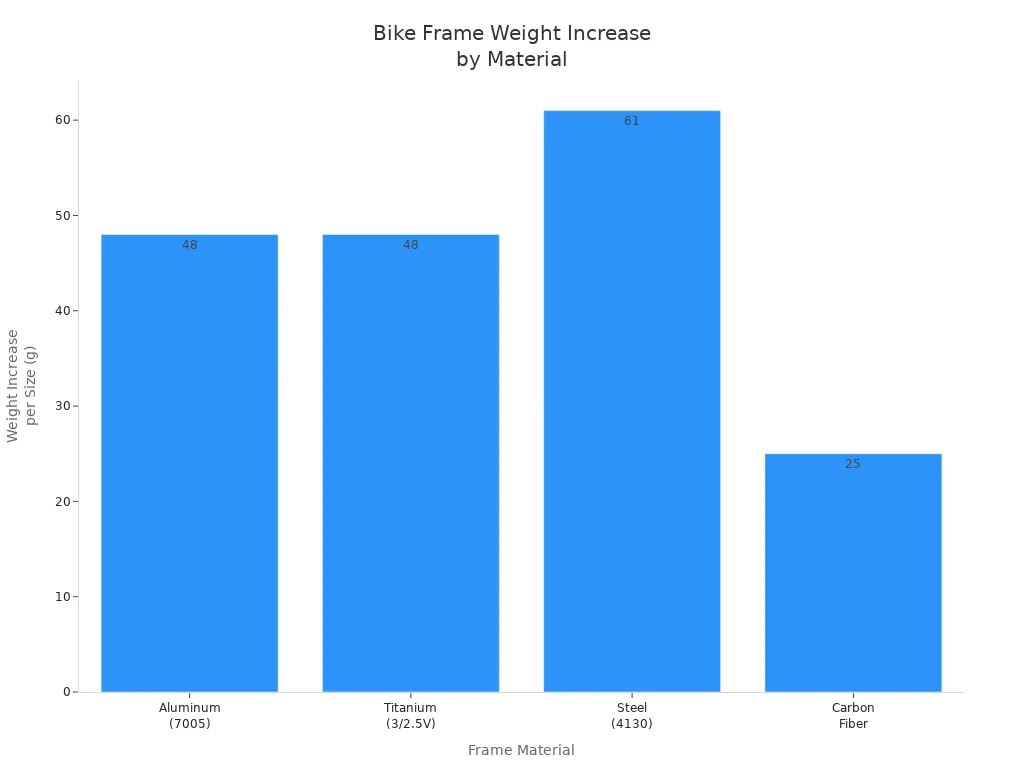

Here is a table that shows how much each material adds to the weight of a medium-sized bicycle frame:

Material | Density (g/cm³) | Total Weight Increase per Frame Size (g) |

|---|---|---|

Aluminum (7005) | 2.8 | ~48g |

Titanium (3/2.5V) | 4.5 | ~48g |

Steel (4130) | 7.8 | ~61g |

Carbon Fiber | ~1.6 | 18-25g |

You see that carbon frames are the lightest. Steel frames are the heaviest. Aluminum and titanium frames are almost the same in weight. If you want a lightweight bike frame, carbon is the best choice. Aluminum and titanium also help you keep your bike light. Steel works well if you do not mind extra weight.

Strength is also important. Carbon and titanium give you high strength for their weight. Aluminum is strong but not as tough as titanium or steel. Steel handles stress well and lasts a long time. You need to think about both weight and strength when you choose your bicycle frame.

Durability and Comfort

Durability means how long your bike frame lasts. Comfort means how smooth your ride feels. You want a bicycle that stays strong and feels good to ride. Steel and titanium frames last a long time. Carbon frames can last many years if you take care of them. Aluminum frames resist rust but may wear out faster.

Here is a table that shows how each material handles fatigue and corrosion:

Material | Fatigue Life Characteristics | Corrosion Resistance Characteristics |

|---|---|---|

Steel | Can handle stress for many years if you keep it dry. Has a fatigue limit. | Needs care to stop rust. Very tough against dents. |

Aluminum | Will wear out after many cycles. No true fatigue limit. | Does not rust. Can get dents more easily. |

Titanium | Handles stress very well. Has a fatigue limit like steel. | Does not rust. Lasts longer than steel. |

Carbon | Can last a long time if you avoid hard impacts. | Does not rust. Needs careful checks for cracks. |

Experts say carbon frames give you the most comfort. You feel less vibration and bumps. Titanium frames absorb shocks and make your ride smooth. Steel frames also feel soft and comfortable. Aluminum frames feel stiff and lively, but can be harsh on rough roads. Modern bike frame design helps aluminum frames feel better, but steel, titanium, and carbon still win for comfort.

Tip: If you want a bicycle for long rides or rough roads, choose steel, titanium, or carbon for the best comfort.

Cost and Value

Cost is a big part of material selection. You want a bicycle that fits your budget and gives you good value. Steel frames cost the least. Aluminum frames cost a bit more. Carbon frames are expensive. Titanium frames cost the most.

Here is a table that shows the price range for medium-sized bicycle frames:

Material | Frame Size | Weight Range Raw Frame (g) | Weight Range Painted Frame (g) | Cost Range (USD) |

|---|---|---|---|---|

Carbon Fiber | Medium | 600 – 1100 | 700 – 1200 | $1000 – $4000+ |

Aluminum (6061) | Medium | 1200 – 1500 | 1300 – 1600 | $300 – $1200 |

Steel (4130) | Medium | 1400 – 1800 | 1500 – 1900 | $250 – $900 |

Titanium | Medium | 1100 – 1500 | 1200 – 1600 | $2000 – $6000+ |

You see that steel and aluminum frames give you good value for the price. Carbon and titanium frames cost more but give you better performance and comfort. If you want a high-performance bicycle, you may need to spend more. If you want a good bike for less money, steel and aluminum work well.

Choosing the Right Bicycle Frame

You need to think about your riding style, terrain, and budget before you pick a bicycle frame. Here is a checklist to help you with material selection:

Weight: Choose carbon or titanium for racing and high performance. Pick steel or aluminum for touring or everyday use.

Purpose: Use stiff and lightweight bike frames for racing. Pick durable frames for long rides or mountain bike frame materials.

Terrain: Ride in wet places with aluminum or titanium. Steel may rust in humid climates.

Longevity: Pick titanium or carbon for long-lasting frames. Steel lasts long but needs care. Aluminum resists rust but may wear out sooner.

Budget: Steel is cheapest. Aluminum costs a bit more. Carbon and titanium cost the most.

Note: Custom bike frames let you pick the best material for your needs. You can choose the shape, weight, and comfort you want.

You need to balance performance, comfort, and cost. If you want a lightweight bike frame for racing, carbon is best. If you want a bicycle for adventure or touring, steel or titanium works well. Aluminum gives you a good mix of price and performance. Custom bike frames let you get the exact bike frame design you want.

When you choose your bicycle frame, think about how you ride, where you ride, and how much you want to spend. You will find the best bike frame tubes for your needs if you use this checklist.

You notice big changes in weight, comfort, and how long frames last. Hi-tensile steel, chromoly steel, aluminum, carbon, and titanium are all different. Aluminum frames make bikes light and simple to care for. Steel frames are strong and give smooth rides. But steel needs care so it does not rust. Carbon frames soak up bumps and help you go fast. You should check carbon frames for damage after crashes. Titanium frames are light and last a long time. They are good for riders who want strong frames. Pick your frame based on how you ride and your budget. Think about price, comfort, and how much work you want to do to keep your bike working well.

FAQ

What is the lightest bike frame material?

Carbon fiber gives you the lightest bike frames. You can lift and move your bike easily. Many racers pick carbon for this reason.

Can you repair a cracked carbon fiber frame?

You can fix some carbon fiber frames, but you need a skilled repair shop. Always check your frame after a crash. If you see cracks, stop riding and get it checked.

Does steel always rust?

Steel can rust if you leave it wet. You can stop rust by keeping your bike dry and using paint or coatings. Chromoly steel resists rust better than hi-tensile steel.

Is titanium worth the high price?

Titanium costs more, but you get a frame that lasts many years. You feel a smooth ride and never worry about rust. If you want a bike for life, titanium is a smart choice.

See Also

Key Materials In Track Bike Frames And Their Importance

Must-Have Tools And Supplies To Build A Bike Frame

Exploring The Innovations In Carbon Fiber Bike Frames

Top Materials That Create The Lightest Bike Frames

Comparing Enduro Bike Frame Materials For Durability And Strength