Choosing the best type of bike frame is very important for your ride. Different materials can affect your performance, comfort, and budget. For example, carbon fiber is lightweight but more expensive, while steel is strong, absorbs bumps well, and is more affordable. When deciding on the best type of bike frame, consider what matters most to you when cycling.

Key Takeaways

Steel frames are strong and last a long time. They absorb shocks well. However, they are heavier and need care to stop rust.

Aluminum frames are light and do not rust. This makes them good for speed and easy to take care of. But they can feel stiff and rough on bumpy roads.

Titanium frames are light and tough. They also resist rust very well. However, they are more expensive and need special skills to fix.

Carbon fiber frames are very light and smooth. They are great for racing. But they cost a lot and need careful handling to avoid damage.

Choosing the right frame depends on how you ride, your budget, and what feels comfortable. Think about weight, durability, and how the ride feels to find the best one for you.

Steel Frames

Steel Advantages

Steel frames have many good points that make them popular with cyclists. First, steel is known for its strength and durability. It can handle a lot of stress and resist wear, making it great for tough use. This means you can trust your steel bike frame for years, even in hard conditions.

Another big plus is the ride quality. Steel frames are great at absorbing shocks, giving you a smooth ride on bumpy paths. They bend a little, which helps soak up bumps and vibrations. This feature makes rides more comfortable, especially on long trips. Many cyclists like how steel frames balance stiffness and comfort, making cycling enjoyable.

Here’s a quick overview of the most common types of steel used in bike frames and their properties:

Steel Type Category | Examples (Reynolds/Columbus) | Mechanical Properties & Notes |

|---|---|---|

Stainless Steels | Reynolds 953, Columbus XCR | High corrosion resistance, high ultimate tensile strength (UTS), suitable for premium frames. |

Air-hardening Steels | Reynolds 853, Reynolds 631 | Harden during welding, excellent fatigue resistance, high strength, good weldability. |

Heat-treated Chrome-Moly Steels | Reynolds 725, Reynolds 753 | Stronger than standard chromoly, heat-treated for improved strength and durability. |

Cold-worked Chrome-Moly Steels | Reynolds 525, Reynolds 520 | Good strength and toughness, more affordable, commonly used in mid-range frames. |

Steel Disadvantages

Even with their benefits, steel frames have some disadvantages. One major downside is their weight. Steel frames are usually heavier than aluminum, titanium, and carbon fiber frames. This extra weight can be a problem for competitive cyclists or those who ride uphill often.

Also, steel frames can rust if not taken care of properly. Regular cleaning and maintenance are important, especially in wet weather. Riders who want low-maintenance bikes might not like this part.

Another issue is that while steel frames stay stiff over time, they can become weak if made poorly. This weakness can cause cracks, which can harm the frame’s strength.

Aluminum Frames

Aluminum Advantages

Aluminum frames have many advantages that make them popular with cyclists. One big benefit is their lightweight nature. Aluminum bike frames usually weigh 1 to 2 pounds less than steel frames. This weight difference can help you go faster and ride better, especially on long rides or hills.

Another important advantage is corrosion resistance. Aluminum creates a protective layer when it gets wet. This layer helps stop rust. This means your bike stays strong in different weather. Unlike steel, which can rust without care, aluminum needs less maintenance.

For strength-to-weight ratio, aluminum alloys like 6061 and 7005 are great. The table below shows their main properties:

Property | 6061 Alloy | 7005 Alloy |

|---|---|---|

Main Alloying Elements | Magnesium (0.8-1.2%), Silicon (0.4-0.6%) | Zinc ( |

Tensile Strength (T6) | 310 MPa | 350 MPa |

Yield Strength (T6) | 275 MPa | 290 MPa |

Weldability | Easily welded | More challenging but possible |

Fatigue Resistance | Good | Better than 6061 |

Weight Advantage | Lightweight | Lightweight |

Aluminum Disadvantages

Even with their many benefits, aluminum frames have some disadvantages. One common issue is their stiffness. While this makes pedaling easier, it can make the ride rougher. Aluminum frames send more road vibrations to you, which can make you tired on long rides.

Also, while aluminum is strong, it does not absorb vibrations like steel. This means you might feel more bumps when riding on rough paths. Some riders like the smoother ride that steel frames give, especially on longer trips.

Titanium Frames

Titanium Advantages

Titanium frames have many advantages that make them popular with serious cyclists. First, titanium has a great strength-to-weight ratio. This means the frame is light but very strong. For example, titanium is about twice as strong as aluminum and 45% lighter than steel. This mix lets you enjoy a strong ride without extra weight.

Another big plus is titanium’s corrosion resistance. Unlike steel, which can rust, titanium makes a protective layer on its own. This helps keep your bike looking nice and working well in different weather. Also, titanium frames are very good at handling stress. They can take repeated bumps and vibrations better than aluminum and steel. This toughness means your bike can last longer, even in tough conditions.

Here’s a quick overview of the mechanical properties of different titanium types used in bike frames:

Property | Pure Titanium | Grade 4 Titanium | 3Al/2.5V Titanium (annealed) | 6-4Ti Titanium (annealed) | Aging Treated Titanium |

|---|---|---|---|---|---|

Tensile Strength (MPa) | 480-620 | 550 | 685 | 980 | 1160 |

Yield Strength (MPa) | 345 | 480 | 590 | 920 | 1100 |

Elongation (%) | 18 | 15 | 20 | 14 | 10 |

Young’s Modulus (GPa) | 105 | N/A | N/A | 110 | N/A |

Titanium Disadvantages

Even with its many advantages, titanium frames have some disadvantages. One main problem is the cost. Titanium frames usually cost much more than steel or aluminum frames. The high price comes from the expensive materials and the hard manufacturing steps needed. For example, welding titanium needs special skills and tools to avoid problems, which raises the cost.

Another issue is the manufacturing complexity. Working with titanium needs skilled workers and special tools. This makes repairs tough, as not all bike shops have what they need. If you need to fix a titanium frame, it might be harder to find someone who can do it right.

Carbon Fiber Frames

Carbon Fiber Advantages

Carbon fiber frames have many big benefits that make them popular with cyclists. First, they are very lightweight. A carbon frame usually weighs about 3.8 kg (8.38 lbs). This is lighter than aluminum frames, which weigh around 4.6 kg (10.14 lbs). This weight difference can help you perform better, especially when climbing hills or on long rides.

Another important benefit is the strength-to-weight ratio. Carbon fiber materials are anisotropic. This means their strength and stiffness change based on how the fibers are arranged. Manufacturers can place the fibers in ways that make the frame stronger. This creates a frame that is light but also strong and good at absorbing bumps. The advanced TIME’s Braided Carbon Structure (BCS) technology makes the frame even tougher. It helps the frame resist small hits and stress over time.

Also, carbon fiber frames are great at vibration dampening. This helps reduce tiredness during long rides. You can enjoy a more comfortable ride. The material can also be shaped into aerodynamic designs that help you go faster and ride more efficiently.

Carbon Fiber Disadvantages

Even with their many benefits, carbon fiber frames have some clear downsides. One big issue is the cost. Carbon fiber frames usually cost between $500 and over $2,000. This makes them much more expensive than aluminum frames. The high price comes from the more costly materials and the complicated process to make carbon bike frames.

Another downside is their susceptibility to damage. While carbon fiber is strong, it can break easily if hit hard. Unlike aluminum frames that might dent or bend, carbon frames can crack from sharp impacts. This means you need to be careful with your carbon bike, especially during crashes or rough handling. If damage happens, special repairs can fix the frame’s strength, but these repairs can be expensive.

Comparing Bike Frame Materials

When picking a bike frame, think about weight, cost, durability, and ride quality. Each material has special traits that can change how you ride.

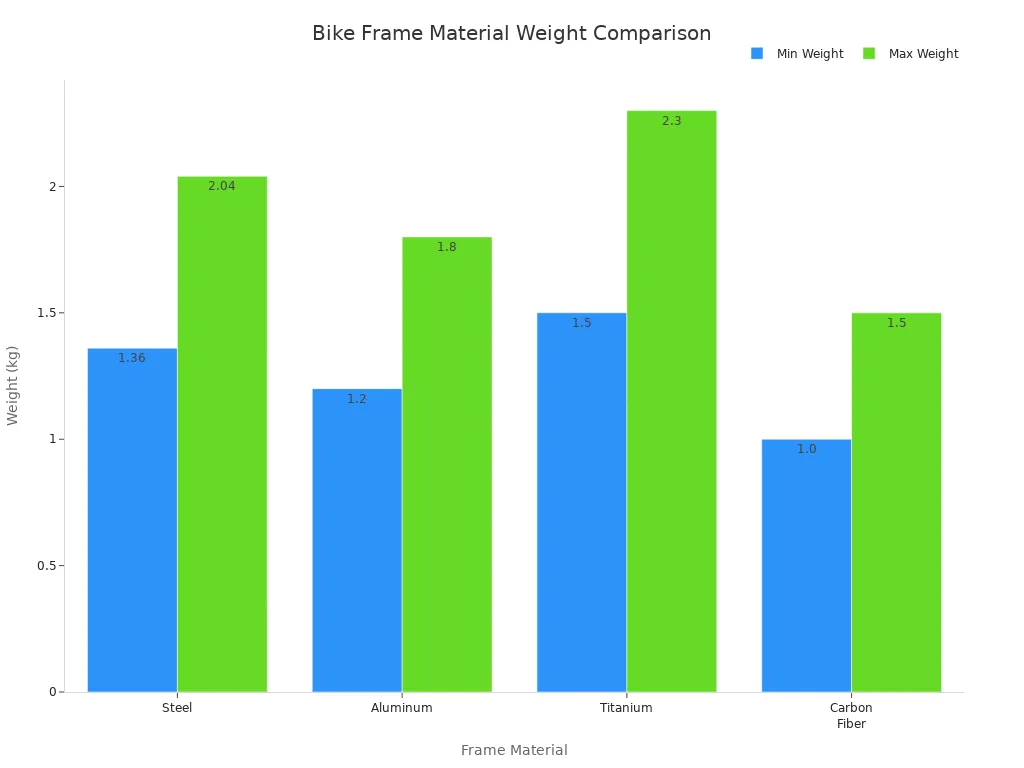

Weight Comparison

Weight is very important for cycling performance. Lighter frames are easier to handle and help you go faster, especially uphill. Here’s how the average weights of different bike frame materials compare:

Material | Average Frame Weight Range (kg) | Notes on Variability and Properties |

|---|---|---|

Steel | Weight changes with tubing type and frame size; strong and durable with some shock absorption. | |

Aluminum | 1.2 – 1.8 | Depends on alloy and design; aerospace alloys can lower weight while keeping strength. |

Titanium | 1.5 – 2.3 | Strong and lightweight (~45% lighter than steel); weight varies with tubing thickness and design. |

Carbon Fiber | 1.0 – 1.5 | Very light and strong; weight affected by fiber layering and curing process. |

As shown, carbon fiber frames are usually the lightest, which can really help your pedaling in races. But not all carbon frames are lighter; lower-grade carbon can weigh as much as aluminum. Aluminum frames have become lighter thanks to better manufacturing, making them a good choice for many riders.

Cost Comparison

Cost is another key factor when choosing a bike frame. Entry-level bike frames usually cost less than $2,000. You can find used bikes for $500 to $999, which are good options. For new or well-kept used bikes with entry to mid-range parts, expect to pay between $1,500 and $2,500.

High-end bikes, especially carbon fiber ones, can cost from about $2,500 to over $17,000. Titanium frames are also pricey because of the material and labor costs. Steel frames are usually cheaper, while aluminum frames are a lower-cost option compared to carbon fiber.

Durability Comparison

Durability is important for long-term use. Here’s how different materials compare:

Frame Material | Durability Rating |

|---|---|

Steel | Highest durability; easy to repair but heavier and can rust. |

Titanium | Highest durability; very tough, rust-resistant, often called a ‘forever bike.’ |

Aluminum | Good durability; stiff and strong but wears out faster, dents instead of cracks, repairs are hard. |

Carbon Fiber | Good durability; great fatigue resistance and strength-to-weight ratio but can crack from impacts; can be repaired by professionals. |

Titanium frames are very durable, resisting cracks and dents. Steel frames are also very durable and easy to fix, making them reliable over time. Aluminum frames can dent and wear out, while carbon fiber frames are strong but can crack from hard hits.

Ride Quality Comparison

Ride quality can be very different among materials. Cyclists often say that ride quality differences depend more on frame design than on the material itself. Here are some points:

Steel frames give a smooth ride because they absorb shocks well.

Aluminum frames send more road vibrations to you, which can make the ride rougher.

Titanium frames can be adjusted for ride quality based on tubing choice and rider weight.

Carbon fiber frames are great at reducing vibrations, leading to a smoother ride and less tiredness.

Good vibration damping makes riding more comfortable, especially on bumpy paths. This helps reduce tiredness during long rides, which is important for both comfort and performance.

Choosing the right bike frame depends on how you ride and where you go. Here’s a quick look at the materials we talked about:

Material | Strengths and Suitability | Weaknesses and Considerations |

|---|---|---|

Steel | Strong, comfy, absorbs shocks; great for off-road and heavier riders | Heavier than aluminum; can rust without care; design affects how it performs |

Aluminum | Resists rust, light, stiff; good for racing and climbing | Rougher ride at lower prices; harder to fix than steel |

Titanium | Light, strong, resists rust, smooth ride on rough paths | Very costly; hard to repair |

Carbon Fiber | Super light, stiff, strong; great for racing and performance | High price; tough to fix; less durable in crashes |

When picking a bike frame, think about what you need. If comfort and durability matter most, steel might be best. For racing, carbon fiber or aluminum could help you perform better. Always keep your budget in mind, as prices can be very different for each material.

FAQ

What is the best bike frame material for beginners?

For beginners, aluminum frames are usually the best option. They are light, cheap, and need less care than steel. Aluminum frames also give a good mix of performance and comfort.

How do I maintain my steel bike frame?

To take care of your steel bike frame, clean it often with soap and water. Make sure to dry it well to stop rust. Use a protective coating or wax to keep it looking nice and to guard against moisture.

Can I repair a carbon fiber frame?

Yes, you can fix a carbon fiber frame, but it needs special skills and materials. Professional bike shops can repair small cracks. However, repairs can be expensive, so be careful with your carbon bike.

How does frame material affect ride quality?

Frame material greatly affects ride quality. Steel gives a smooth ride because it absorbs shocks well. Aluminum is stiffer, which can make the ride bumpier. Carbon fiber reduces vibrations, making for a comfy ride.

Is titanium worth the investment?

Titanium frames are worth the money if you want durability and performance. They resist rust and have a great strength-to-weight ratio. However, their higher price might not fit every budget.

See Also

Evaluating Enduro Bike Frame Materials For Durability And Strength

Advantages And Disadvantages Of Aluminum Bike Frame Strength

Best Materials Used In Electric Bike Frames And Benefits

Comparing Carbon Aluminum And Steel Bike Frames For Buyers

Track Bike Frame Materials And Their Importance Explained Clearly