A lugged bike frame has steel tubes joined by lugs. These lugs are sleeves on the outside of the tubes. People often like these frames for their classic look. They also notice the small, nice details. Builders use brazing to connect the tubes and lugs. Many cyclists like lugged bike frames for their old-fashioned beauty. They also like the link to old ways of making bikes. This frame can use special kinds of steel. This style gives a vintage feel that is easy to spot today.

Key Takeaways

Lugged bike frames connect steel tubes with outside sleeves called lugs. This makes bikes strong and gives them a classic look. Builders use brazing with metals like brass or silver to join tubes and lugs. This helps make repairs simple and keeps frames tough. Good steel alloys like chromoly and stainless steel make lugged frames strong and comfy. They also help bikes ride smoothly. Lugged frames are easy to fix and have a style that never gets old. You can change them to fit your needs, but they are heavier and cost more than welded frames. People who like tradition, strong bikes, and easy care often pick lugged frames for commuting, touring, or custom bikes.

Lugged Bike Frame Basics

What Is a Lugged Bike Frame

You may ask what makes a lugged bike frame special. In bike building, a lugged bike frame uses steel tubes joined by lugs. Lugs are socket-like pieces that fit over the tube ends. The tubes are cut and shaped to fit inside the lugs. Lugs act like sleeves and hold the tubes in place before joining.

Lugged bike frames are known for their classic way of building bikes. Builders use brazing, which melts a filler metal like brass or silver. The melted metal flows between the tube and the lug. This makes a strong bond and covers a big area. You can spot lugs at the seat lug, bottom bracket shell, and head lugs. Each lug connects important frame parts and shapes the bike.

Note: Lugged frames are famous for being well-made and easy to fix. If a tube breaks, you can heat the joint and take out the tube. You can put in a new tube without hurting the rest of the frame.

Many riders like lugged frames for their strength, repair options, and classic style. You will see vintage bikes and some new custom bikes use this method. It lets builders make frames with exact shapes and nice details.

How Lugs Connect Tubes

Lugs are very important in making a lugged bike frame. Here is how it works:

First, steel tubes are cut and shaped to fit into the lugs.

Next, you put the tube ends into the lugs and line them up.

During brazing, you use brass filler metal. The melted metal fills the gap between the tube and the lug.

This spreads the filler metal over a big area and makes the joint strong.

Lugs make each connection stronger and help the frame last longer.

If you need to fix the frame, you can heat the joint and remove the tube. You can put in a new tube, which makes repairs easier than with other frames.

Builders use jigs to keep the tubes and lugs lined up during building.

Common lugs are the seat lug, bottom bracket shell, and head lugs. Each one connects key frame parts and shapes the bike.

Lugs do more than just hold tubes together. They help make a strong and long-lasting frame. They also let builders shape the frame exactly. Lugged frames are still liked by riders who want tradition, strength, and easy repairs.

Lugged Frame Construction

Materials Used in Lugged Frames

When you look at a lugged frame, you see steel tubes joined by socket-like lugs. The choice of steel alloy shapes the strength, weight, and ride quality of your bike. Most lugged frames use high-quality steel, such as chromoly or stainless steel. These materials offer a balance of durability, flexibility, and repairability. Chromoly steel stands out for its strength and ability to be made into thin, light tubes. Stainless steel resists rust and keeps its shine for years.

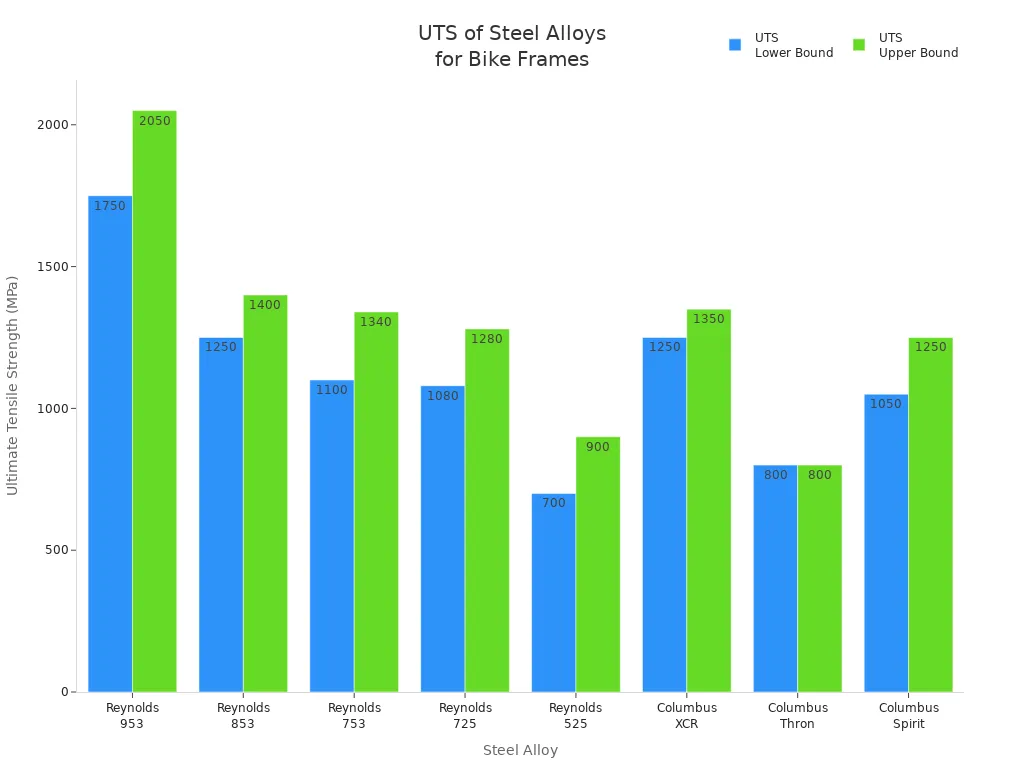

Here is a table showing some common steel alloys used in lugged bike frame construction:

Steel Alloy | Type/Description | Ultimate Tensile Strength (UTS) | Key Properties and Notes |

|---|---|---|---|

Reynolds 953 | Martensitic-aging stainless steel | 1750-2050 MPa | Extremely high strength, fatigue resistant, impact resistant, needs special fabrication. |

Reynolds 853 | Heat-treated, air-hardening steel | 1250-1400 MPa | Strength increases after welding, thin walls, lightweight, stiff, fatigue resistant. |

Reynolds 753 | Manganese-molybdenum heat-treated | 1100-1340 MPa | High strength, lightweight, responsive ride, needs certified silver brazing. |

Reynolds 725 | Heat-treated chrome-molybdenum steel | 1080-1280 MPa | Ductile, oxidation resistant, weldable, often used with other tubes. |

Reynolds 525 | Cold-worked chrome-molybdenum steel | 700-900 MPa | Non-heat-treated, TIG weldable, lower cost, less strength than heat-treated alloys. |

Columbus XCR | Martensitic stainless steel | 1250-1350 MPa | High fatigue resistance, excellent weldability, corrosion resistant, lightweight and durable. |

Columbus Thron | High-performance steel with carbides | 800 MPa | Keeps properties during brazing, good mechanical characteristics. |

Columbus Spirit | Niobium-alloyed heat-treated steel | 1050-1250 MPa | Superior mechanical characteristics, high environmental resistance, lightweight and reliable. |

You can see that each alloy brings different strengths and qualities. For example, Reynolds 953 offers very high strength and impact resistance, while Reynolds 525 is more affordable but less strong. The tubing’s diameter and wall thickness also affect the frame’s weight and ride feel. Thicker tubes add weight but resist dents. Thinner tubes save weight but can dent more easily.

When you choose a lugged frame, you get a bike that balances strength, comfort, and repairability. Steel’s elastic nature helps absorb bumps, making your ride smoother. This is why many hand made bicycles and touring bikes use steel for their frames.

Brazing and Assembly

Brazing is the heart of lugged frame construction. You join the steel tubes and lugs using a filler metal, such as brass or silver alloy. The process uses heat, but not enough to melt the steel tubes. This keeps the steel strong and keeps its special properties.

Here is how the brazing and assembly process works:

Gather your tubes, lugs, bottom bracket shell, dropouts, flux, and safety gear.

Clean the lugs inside so they fit smoothly over the tubes.

Cut and file the tube ends to match the shape of the lugs. This step is called mitering.

Set up the frame in a jig. The jig holds everything in place and keeps the frame straight.

Apply flux to the tube ends and lugs. Flux stops the metal from rusting during heating.

Fit the tubes into the lugs and secure them in the jig.

Heat the joint with a torch. The filler metal melts and flows into the gap between the tube and the lug.

Let the joint cool, then check the alignment.

Repeat for each joint, building the main triangle first, then the rear triangle.

Finish the outside of the lugs by sanding or carving for a smooth look.

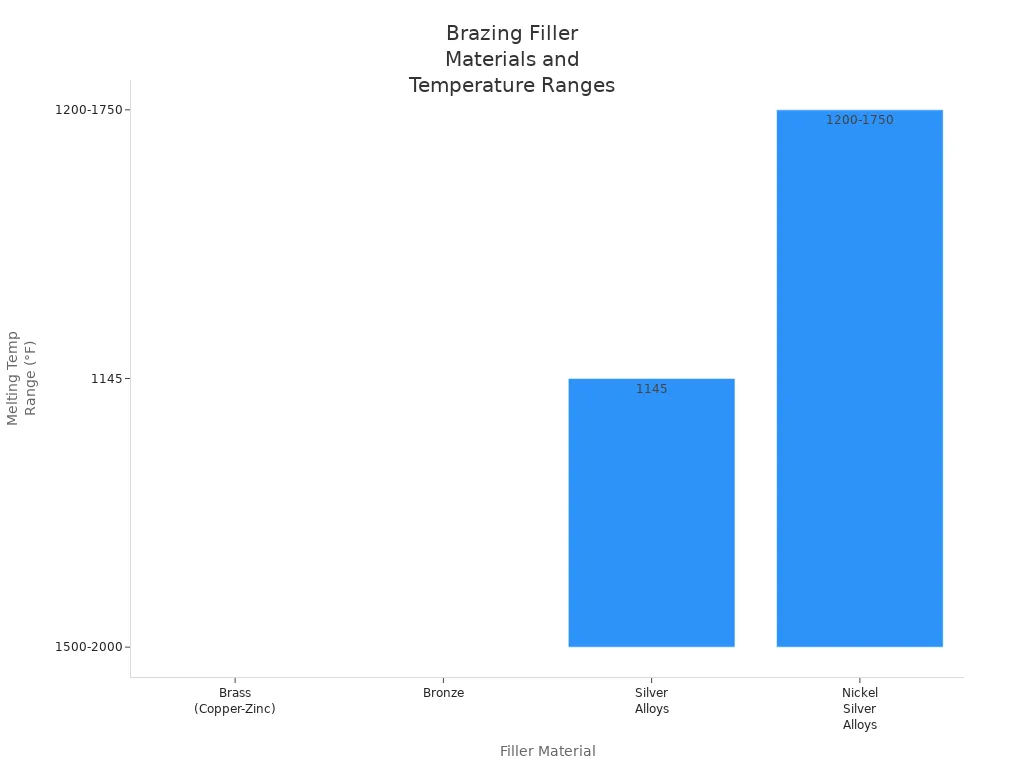

Brazing temperatures stay above 840°F but below the melting point of steel. This protects the steel’s strength. You can use different filler metals, each with its own melting range:

Filler Material | Typical Melting Temperature Range | Notes |

|---|---|---|

Brass (Copper-Zinc) | Over 1500°F, up to 2000°F | Common for non-heat-treated steel, cost-effective, forgiving process. |

Bronze | Over 1500°F, up to 2000°F | Similar to brass, used in lug brazing. |

Silver Alloys | As low as 1145°F | Lower temperature, stronger joints, often 20-60% silver content. |

Nickel Silver Alloys | 1200°F to 1750°F | Not true silver, stronger than brass, wide working range. |

Tip: Brazing keeps the steel’s heat treatment safe. This means your frame stays strong and flexible after joining.

The way you assemble the frame matters. You use a jig to keep everything lined up. You check each joint after brazing to make sure the frame stays straight. This careful process helps your bike last longer and ride better.

Lug Manufacturing Methods

Lugs are the key connectors in a lugged frame. They act like sleeves, holding the tubes in place for brazing. The way you make lugs affects the look and strength of your bike.

Most lugs are made by investment casting. This method lets you create detailed shapes and smooth surfaces. Some lugs, like seat lugs, may have extra features such as binder bolt housings. These features help attach parts like the seat post to the frame. Sometimes, builders use forging or machining for special lugs, but casting is the most common.

Craftsmanship plays a big role in lugged frame construction. Skilled builders align the tubes with care and choose the right lugs for each frame. They can add custom touches, like special dropouts or cable guides. Good craftsmanship means your frame will last longer, look better, and ride smoother.

Precise tube alignment gives you a frame that handles well.

Custom features make your bike unique and fit your needs.

High-quality materials and careful work help your frame resist rust and damage.

A well-made lugged frame is easy to repair and can last for decades.

When you choose a lugged frame, you get more than just a bike. You get a piece of skilled work that blends tradition, strength, and beauty.

Lugged Frame Pros and Cons

Strength and Durability

If you pick a lugged bike frame, it will last a long time. Steel frames like these can last for many years if you take care of them. You should keep your frame clean and dry so it does not rust. Steel is strong and can handle stress without breaking down fast.

Lugged frames move stress away from the joint. This means the tubes must be thicker to handle the extra force, sometimes up to three times thicker than tubes in TIG or fillet brazed frames.

TIG welding uses very high heat. This can make thin tubes weak and cause them to break near the weld.

Fillet brazing uses lower heat. This makes the frame stiffer and helps stop weak spots at the joints.

Lugged frames can be heavier, but they are safer and easier for small builders to make than TIG or fillet brazed frames.

Repair and Modification

Lugged frames are easier to fix than many welded frames. The most common fix is to replace a tube using brazing. This works because the tubes fit into lugs, so you can take out a broken tube and put in a new one without hurting the rest of the frame. Many people say their repairs last for years with no trouble.

Repairs do not happen often, but they can cost a lot, especially if you need new paint.

Lugged frames make it easier to swap out tubes than welded frames.

Changing a lugged frame, like adding braze-ons or inside cable routing, is possible but takes a lot of work. You may have to take apart parts like the headset and bottom bracket.

Adding new features, like disc brakes or thru axles, is hard and not usually a good idea.

Limitations

There are some things lugged frames cannot do.

Lugs come in set angles and shapes, so you cannot change the frame shape much. You cannot easily make sloping top tubes or use big or oval tubes.

Making special lugs for custom shapes costs a lot and is not easy.

Welding lets builders use many tube sizes and shapes. This makes lighter and more creative frames.

Lugged frames weigh more because lugs add weight and the tubes must be thicker.

Lugged frames cost more because they need skilled work and extra parts. Welding is faster, can use machines, and uses butted tubes for lighter, cheaper frames.

Note: Lugged frames look classic and are easy to fix, but they are heavier, cost more, and cannot be changed as much as welded frames.

Lugged Frame Aesthetics

Customization and Style

You can make a lugged bike frame truly your own. Custom bike builders offer many ways to change the look and feel of your frame. You get to choose paint colors, lug shapes, and special details. The table below shows how much you can customize at different levels:

Customization Level | Paint Options | Lug Shape Customization | Detailing Options |

|---|---|---|---|

Standard-Level | Basic paint | Hand-formed needle-point lugs, thinned edges | Simple shaping, careful hand forming |

Ultra-Level | Customized paint | Unique lug shapes, stylized arrowheads | Added lug points, stainless steel parts, extended designs |

Signature-Level | Fully custom paint, tri-chrome racks | Most creative lug shapes, carried into fork crown | Exotic inlays, intricate craftsmanship |

You can ask for lugs with special shapes, like arrowheads or even your initials. Some builders thin the edges of lugs to make them look elegant, but they keep the frame strong. You may see extra details, such as stainless steel rack mounts or bottle holders. These touches make your bike stand out and show off the builder’s skill.

Custom lug designs let you express your style. You can pick colors and patterns that match your taste. Builders can add inlays or carve shapes into the lugs, turning your frame into a work of art.

Visual Appeal

Lugged bike frames catch your eye with their unique look. You see metal sleeves, called lugs, at the joints where tubes meet. These lugs often have patterns that are hand-cut and filed. You notice the craftsmanship in every detail. Custom lugs can feature floral shapes or other creative designs. These details highlight parts of the bike, like the head tube, and blend beauty with strength.

If you compare lugged frames to welded or fillet-brazed frames, you spot the difference right away. Welded frames have smooth joints with no extra shapes. Fillet-brazed frames look clean and simple, with no lugs at all. Lugged frames stand out because of the visible lugs and the patterns they show. You see the builder’s skill and creativity in every joint.

Lugged frames show off tradition and artistry.

You get a bike that looks classic and feels special.

Custom bike builders can turn your ideas into a frame that is both strong and beautiful.

Tip: If you want a bike that reflects your personality, a lugged frame gives you endless options for style and detail.

Choosing a Lugged Frame

Practical Considerations

When you pick a lugged bike frame, think about how you will use it. If you ride to work, you need a frame that can handle daily trips and bumpy roads. Steel frames are good for commuting because they last long and do not break easily. You can add racks and bags to carry your things. This makes your bike helpful for work or shopping. Touring riders need frames with eyelets for racks and room for bigger tires. This setup gives comfort and lets you carry bags on long rides.

Racing needs something different. You want a frame that is stiff for fast turns and speed. Lugged frames can work for racing, but you must check if the shape fits your needs. You also want a frame that feels light but stays strong. Price is important, especially for people who ride to work. Many riders look for frames under $200 that are still good quality.

Tip: Lugged frames let you change parts easily. You can switch racks, bags, or even child seats. This means one bike can do many jobs.

Repairing a lugged frame is easy. If your frame gets hurt, you can fix it without buying a new bike. Brazing uses less heat than welding, so repairs do not make the steel weak. You can keep your frame for many years if you take care of it.

Who Should Choose Lugged

You might wonder if a lugged frame is right for you. Riders who like to do many things and people who go on long trips often pick lugged steel frames. These frames are strong and feel smooth to ride. BMX racers, especially kids, like chromoly steel frames because they do not break in crashes and fit as they grow. People who like old-style bikes and strong frames also choose lugged frames. Gravel and endurance riders like lugged frames because they are stiff but also bend a little.

If you want comfort, easy repairs, and a classic look, a lugged frame is a good choice. Riders who do not want to buy new bikes often and want simple repairs like lugged frames. You may not pick a lugged frame if you want the lightest bike or need a special shape that only welding can make. Custom bike makers can help you see if a lugged frame is right for you.

Rider Type | Why Choose Lugged Frame |

|---|---|

Commuter | Strong, easy to fix, holds accessories |

Touring Cyclist | Lasts long, carries bags, easy to fix |

BMX Racer | Handles crashes, fits growing kids |

Gravel/Endurance | Stiff, bends a bit, lasts long |

Retro Enthusiast | Old-style look, strong build |

You now know lugged bike frames use steel tubes and lugs for strong, classic construction. These frames offer easy repairs, durability, and timeless style. You may notice some drawbacks, such as extra weight and rust risk. If you want a frame that fits your size and riding style, check the table below:

Rider Type | Best Frame Features |

|---|---|

Youth | Shorter top tube, light |

Tall Adult | Longer top tube, strong |

Touring | Tire clearance, comfort |

Hand made bicycles from custom bike builders let you choose details that match your needs and taste.

FAQ

What makes a lugged bike frame different from a welded frame?

You see lugs at the joints on a lugged frame. Welded frames have smooth joints with no extra pieces. Lugged frames use sleeves to join tubes, which gives them a classic look and makes repairs easier.

Can you repair a lugged bike frame if it gets damaged?

Yes, you can repair a lugged frame. You heat the joint, remove the damaged tube, and fit a new one. This process works well for hand made bicycles and helps your frame last longer.

Why do some riders choose lugged frames over modern designs?

You might pick a lugged frame for its classic style, smooth ride, and easy repairs. Many custom bike builders offer unique details and finishes that make your bike stand out from mass-produced models.

Are lugged frames heavier than other types?

Lugged frames often weigh more than welded frames. The lugs and thicker tubes add weight. You get extra strength and a traditional look, but you may notice the extra weight on steep hills.

Can you use modern components on a lugged bike frame?

You can use many modern parts on a lugged frame. Some new features, like disc brakes or thru axles, may not fit without special lugs. Always check with your builder before choosing parts.

See Also

Step-By-Step Guide To Welding A Drift Trike Frame

Key Differences Between Fat And Mountain Bike Frames

Essential Materials For Track Bike Frames And Their Importance

Understanding Full Suspension Bike Frames And Their Functionality