Science and engineering ideas play a crucial role in improving bike frame design. Heat-treated aluminum alloys can become much stronger, allowing frames to be lighter while still maintaining safety. Riders notice these improvements when they ride, as bikes handle better and remain steady. This is especially beneficial in races or long rides. Engineers use computer tests to evaluate tube shapes, finding that oval tubes hold up better than round ones. Every change in bike frame design, whether in shape or material, impacts how the bike performs and feels.

Key Takeaways

Steel, aluminum, titanium, and carbon fiber are used for bike frames. These materials change how strong, light, and tough the frame is. This helps riders pick the best frame for what they need.

The shape and geometry of a bike frame matter a lot. They change how the bike handles and balances. This makes the bike more comfortable and easier to control for each riding style.

Engineers use computer simulations and special tests to improve frames. They make frames stiffer, stronger, and more comfortable. This helps riders use their power better and have smoother rides.

New technology like 3D printing and smart materials helps bike makers. They can make frames lighter, faster, and tougher for each rider.

Modern bike frames mix old designs with new smart features. These include hidden cables and electronic shifting. These features make bikes safer, faster, and more fun to ride.

Frame Materials

Material Comparison

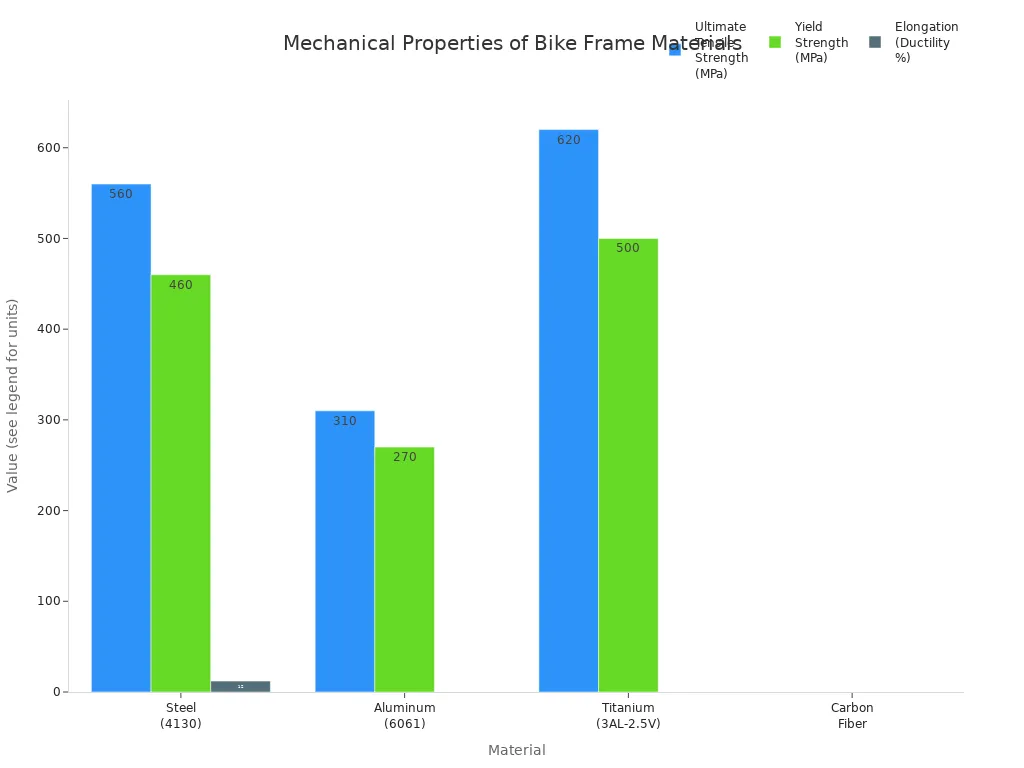

Bike frames are made from different materials. Each material helps balance strength, weight, and how long the frame lasts. Engineers pick steel, aluminum, titanium, or carbon fiber for different riders. Steel is strong and easy to fix. Aluminum is lighter but needs careful design to stop it from wearing out. Titanium is strong and comfortable but costs more and is harder to make. Carbon fiber is very strong for its weight and can be shaped in many ways. The table below shows how these materials compare in strength and how well they resist wearing out:

Material | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Fatigue Resistance / Limit |

|---|---|---|---|---|

Steel (CrMo) | ~560 | ~460 | 9 – 25 | |

Aluminum (6061) | ~310 | ~270 | Lower than steel | No fatigue limit |

Titanium (3AL-2.5V) | ~620 | ~500 | High | Has fatigue limit |

Carbon Fiber | Varies by layup | N/A | N/A | Depends on layup |

Weight and Durability

Frame butting makes bikes strong but not too heavy. Tube walls are thinner in the middle and thicker at the ends. This saves up to two kilograms but keeps the frame tough. Steel frames weigh more but last a long time and do not break easily. Aluminum frames are lighter and stiff but need thicker tubes to stop them from wearing out. Titanium frames are light, strong, and do not rust, but they cost more and are hard to make. Carbon fiber frames are the lightest and stiffest, but they can break quickly if damaged. Lab tests show that good aluminum and carbon fiber frames can last as long as steel if they are designed well.

Stress Distribution

Stress distribution is important for how long a frame lasts and for safety. Engineers use computers to find where stress is highest, like near welds and joints. Riding on rough ground or standing up to pedal adds more stress. Good design spreads out the stress so cracks do not form. Carbon fiber frames use fibers that run in one direction to help spread stress. This lets the fibers carry weight better. Frames that manage stress well last longer and work better for everyone.

Bike Frame Design

Diamond Frame Structure

The diamond frame is the main type used today. It has two triangles. The first triangle uses the head tube, top tube, down tube, and seat tube. The second triangle uses the seat tube, chain stays, and seat stays. In the late 1800s, frames were made from heavy steel. Now, they use lighter materials like aluminum, titanium, and carbon fiber. These new materials make frames stiffer and lighter. They also help frames last longer. Isaac R Johnson was one of the first inventors. He helped create the diamond frame. Today, carbon fiber frames use one-piece molding. This makes them stronger and smoother to ride.

Geometry and Handling

Bike frames use geometry to help with balance. A longer wheelbase makes bikes more stable. This helps riders go straight at high speeds. A shorter wheelbase lets bikes turn faster. But it can feel twitchy. The head tube angle is important too. A slacker angle makes bikes more stable. A steeper angle helps bikes turn quickly. Fork offset and trail change how bikes steer. Modern bikes use these features for different riding styles. Racing bikes have sharp geometry for speed. Endurance bikes have relaxed geometry for comfort. Riders test bikes at different speeds to find what works best.

Rider Comfort

Rider comfort comes from frame design and geometry. The seat tube angle changes where the rider sits. Steeper angles move the rider forward. This helps with climbing and keeps the front wheel steady. Studies show steeper angles can lower muscle strain. They also help riders use more power. Modern bikes use these angles for comfort on long rides. Some bikes have seats that adjust to the rider. Pressure sensors help make riding more comfortable. Endurance bikes have longer wheelbases and relaxed geometry. They absorb bumps better than racing bikes. This makes them good for rough roads.

Engineering Principles

Stiffness and Power Transfer

Stiffness means the bike frame does not bend much. When you push hard on the pedals, a stiff frame helps your energy go to the wheels. This makes the bike feel quick and easy to control. Engineers use different ways to test and improve stiffness. They use Finite Element Analysis (FEA) to see how frames handle stress. FEA breaks the frame into small pieces and checks each one on a computer. This helps engineers find weak spots and make the frame stronger.

Engineering Principle | Explanation | Relevance |

|---|---|---|

Finite Element Analysis (FEA) | Breaks down frame into small elements to analyze stress and strain | Helps optimize frame geometry and materials for stiffness and strength |

Minimizing Strain Energy | Reduces energy lost to frame flexing | Improves power transfer by keeping more energy in the drivetrain |

Directional Stiffness | Stiffness varies by direction; not all forces act the same way | Engineers focus on making frames stiff where it matters most |

Fatigue Strength and Material Properties | Studies how materials handle repeated stress | Ensures frames last longer and stay safe |

Energy Method of Frame Optimization | Uses strain energy as a way to compare and improve designs | Balances stiffness, weight, and strength for better performance |

Practical Examples | Trek 770 and Trek 2000 used these methods to improve their frames | Shows real-world success of these engineering principles |

Lateral flex is when the frame moves side-to-side. If this happens, some energy is lost. The bike can feel less strong and fast. Engineers use wider tubes and oval shapes to stop this flex. Special frame designs help too. Triangles in the frame make it harder to bend. Cargo bikes and bikes that carry heavy things need extra stiffness. Even small changes in design can change how the bike feels.

Lateral rigidity is important for bikes that carry heavy loads or go fast.

Wider tubes and oval shapes make frames stiffer from side to side.

Triangles in the frame help stop side-to-side bending.

Stiff rear ends and racks keep the frame strong.

Drivetrain parts like cranksets are stiffer now, but frame and wheel flex still matter most for how well the bike works.

Compliance and Vibration

Compliance means the frame can bend a little to soak up bumps. This makes riding smoother and more comfortable. Engineers look at how vertical and lateral compliance help comfort. They check the materials and how thick the tubes are. A thinner seat tube lets the frame bend more up and down. This helps take away shocks from rough roads.

A study showed that making the seat tube thinner made the ride softer. It also found that changing the frame shape could help with compliance without making the frame twist too much. Another test used sensors to see how frames handled vibrations. The results showed that side-to-side flex helped comfort more than up-and-down flex. Frames that bent more sideways soaked up bumps better. This means that how a frame bends sideways can really change how comfortable it feels.

Tip: Riders who want a smoother ride should look for frames with good lateral compliance and use flexible parts like wider tires or special seat posts.

Aerodynamics

Aerodynamics is about how air moves around the bike and rider. Less air resistance helps the bike go faster with less work. Engineers use computers and wind tunnels to test frame shapes. They use Computational Fluid Dynamics (CFD) to try many designs on a computer. Wind tunnel tests with mannequins help check these ideas in real life.

Aero tube shapes, like airplane wings, help the bike move through air better. These shapes can lower drag by up to 20%. Carbon fiber lets engineers make these tricky shapes. This material comes from aerospace and helps make frames light and strong. UCI rules limit how thin and long these shapes can be, but engineers still find ways to make bikes faster. Top brands use CFD and wind tunnels to test and improve their bikes. They try to balance aerodynamics, stiffness, and comfort for the best ride.

Note: Aerodynamic frames help riders save energy, especially at high speeds or in races. Even small changes in tube shape can make a big difference.

Technological Innovations

Advanced Manufacturing

Bike frame making has changed a lot with new tech. Automation like Automated Fiber Placement and filament winding helps make frames faster. Large-format 3D printing also makes frames more exact. These methods let companies build custom frames for each rider. The Emery One bike frame uses carbon fiber 3D printing. This lets designers change shapes and stiffness in new ways. Titanium 3D printing makes strong, light frames with special patterns. Nanomaterials like carbon nanotubes and graphene make frames stronger. They also help control heat and vibration. The table below lists these new ideas and their benefits:

Advancement Type | Description | Benefits |

|---|---|---|

Titanium 3D Printing | Lattice structures save weight and add strength | Custom fit, high durability |

Continuous Carbon Fiber 3D Printing | Exact fiber placement changes stiffness | Better damage resistance, tailored ride feel |

Nanomaterials (CNTs, Graphene) | Added to composites for better properties | More strength, better vibration damping |

Hybrid Materials | Mix metals, composites, and nanomaterials | Best balance of weight, strength, and durability |

Automation Technologies | AFP and 3D printing for quick, custom building | Less waste, more sustainable |

Smart Materials

Smart materials are changing how bikes work and last. Some frames use adaptive compliance to change stiffness on the road. This makes rides smoother and helps riders go faster. Self-healing materials fix small cracks by themselves. This helps frames last longer. 3D-printed parts can fit a rider’s body better. This improves comfort and power. These smart materials make new frames lighter, stronger, and more comfortable.

Note: Smart materials also help add electronics, making bikes easier to use.

Modern Integration

Modern integration mixes new tech with old bike frame ideas. Some steel frames, like the Tumbleweed Prospector, use classic shapes but add new features. These include adjustable brackets, space for wide tires, and spots for racks and bottles. Framework Bicycles uses CNC aluminum lugs and carbon fiber tubes. This lets them change geometry and stiffness. Modern bikes often hide cables inside the frame. This helps with aerodynamics and gives a clean look. Electronic shifting systems use wires or wireless signals for smooth shifting. High-end bikes now have smart lights, radar for safety, and power meters for training. These features make bikes safer, faster, and more fun.

Bike frame engineering keeps getting better. This helps make bikes stronger and faster for everyone. The table below shows how new materials and wheel sizes help bikes work better and change what people want to buy:

Frame Material | Key Strengths | Market Trend |

|---|---|---|

Carbon Fiber | High speed, stiffness | More racers use it now |

Aluminum | Lightweight, durable | Many casual riders like it |

Titanium | Premium strength | High-end buyers choose it |

Steel | Smooth ride, repairable | Touring riders trust it |

Riders get more comfort, better control, and more speed from new frame shapes and materials.

Aerodynamic shapes and new things like 3D printing help riders go farther with less work.

Experts think future frames will use new composites, green materials, and custom shapes. Bike frames will keep getting lighter, stronger, and better for the planet. This will help all riders have more fun on their bikes.

FAQ

What makes carbon fiber frames so popular?

Carbon fiber frames are strong and light. Engineers can shape tubes for speed and comfort. Racers like carbon fiber for stiffness and aerodynamics.

Tip: Riders who want the lightest bike pick carbon fiber.

How does frame geometry affect bike handling?

Frame geometry changes how a bike feels. A longer wheelbase makes bikes stable. A shorter wheelbase helps bikes turn quickly. Head tube angle changes steering and control.

Racing bikes have sharp angles for speed.

Endurance bikes have relaxed angles for comfort.

Why do some riders prefer steel frames?

Steel frames last long and are easy to fix. They absorb road bumps well. Touring riders trust steel for smooth rides and durability.

Feature | Steel Frame Benefit |

|---|---|

Longevity | High |

Comfort | Smooth |

Repairability | Easy |

What is frame butting and why is it important?

Frame butting makes tube walls thin in the middle and thick at the ends. This saves weight and keeps frames strong where needed.

Note: Butted tubes help bikes stay light and strong.

Can smart materials improve bike safety?

Smart materials can change stiffness or fix small cracks. These features help frames last longer and keep riders safe. Some smart frames use sensors for better control.

Self-healing materials fix damage.

Adaptive frames adjust to road conditions.

See Also

The Role Of Science In Carbon Frame Repairs

Discovering The Innovations In Carbon Fiber Frames

Understanding Magnesium Frames’ Strength And Lightweight Benefits

Comparing Enduro Frame Materials For Durability And Strength