Welding titanium bike frames is crucial for creating durable and lightweight bicycles. Titanium’s strength and resistance to rust ensure that when you weld titanium, your bike frame lasts longer. This is why many cyclists prefer titanium frames. Understanding the main techniques and preparation steps will help you master the art of welding titanium bike frames, ensuring your bike frame remains in excellent condition for years to come.

Key Takeaways

Pick the right titanium alloy, like Grade 5 or Grade 9. These alloys are strong and light for bike frames.

Keep everything clean before you start welding. Use nitrile gloves and strong cleaners. This helps avoid dirt that can weaken welds.

Use TIG welding for better precision and control. This method makes strong, high-quality welds that look nice.

Watch the heat closely while welding. Low heat settings stop warping and cracking in titanium frames.

Check your welds often and practice regularly. This will help you get better and make strong bike frames.

Welding Preparation

Welding titanium bike frames needs careful planning. You must pick the right materials and keep everything clean for good welds.

Selecting Materials

Choosing the right titanium alloy is important for your bike frame’s performance. The most common grades for bike frame welding are:

Grade 5 (Ti-6Al-4V): This alloy has 6% aluminum and 4% vanadium. It is strong and flexible.

Grade 9 (Ti-3Al-2.5V): This alloy contains 3% aluminum and 2.5% vanadium. It has a great mix of strength, weight, and resistance to wear.

Both grades are popular for bike frames because of their:

Weight: They are light, improving bike performance.

Fatigue Resistance: They handle repeated stress well.

Ease of Welding: This helps in making complex frame designs.

Using the right titanium alloy affects how long your bike frame lasts and its weight. Titanium is very strong but light, making it as strong as steel while being much lighter. This helps you build bike frames that are tough and light, improving your ride. Also, titanium resists rust, so it stays safe from moisture and salt. This means it lasts longer and needs less care.

Cleaning Techniques

Keeping things clean is very important when welding titanium. Dirt can cause bad welds and problems with the frame. Here are some cleaning tips to avoid dirt during welding:

Wear nitrile gloves when touching titanium. This stops oil or dirt from getting on the weld.

Clean the titanium with a strong cleaner like acetone or MEK on a lint-free cloth.

Grind or file the surfaces to take off oxides, grinding slowly to keep heat low.

Don’t use steel wool or rough materials that can dirty the metal.

Wipe the base metal again with acetone or MEK and let it dry before welding.

Clean the filler metal with acetone or MEK and store it right to keep it clean. Cut the end of the filler rod just before welding to show clean titanium.

Not cleaning well can cause big problems, like scratches on the frame, rust on titanium, and bad finishes that hurt weld quality. So, you must keep the weld wire and joints clean before welding.

By following these steps before welding, you can greatly increase your chances of welding titanium bike frames successfully. Making sure joints fit well is key to avoid burning through and bending. Keeping materials clean is very important to stop dirt, as titanium can easily get contaminated.

Best Way to Weld Titanium

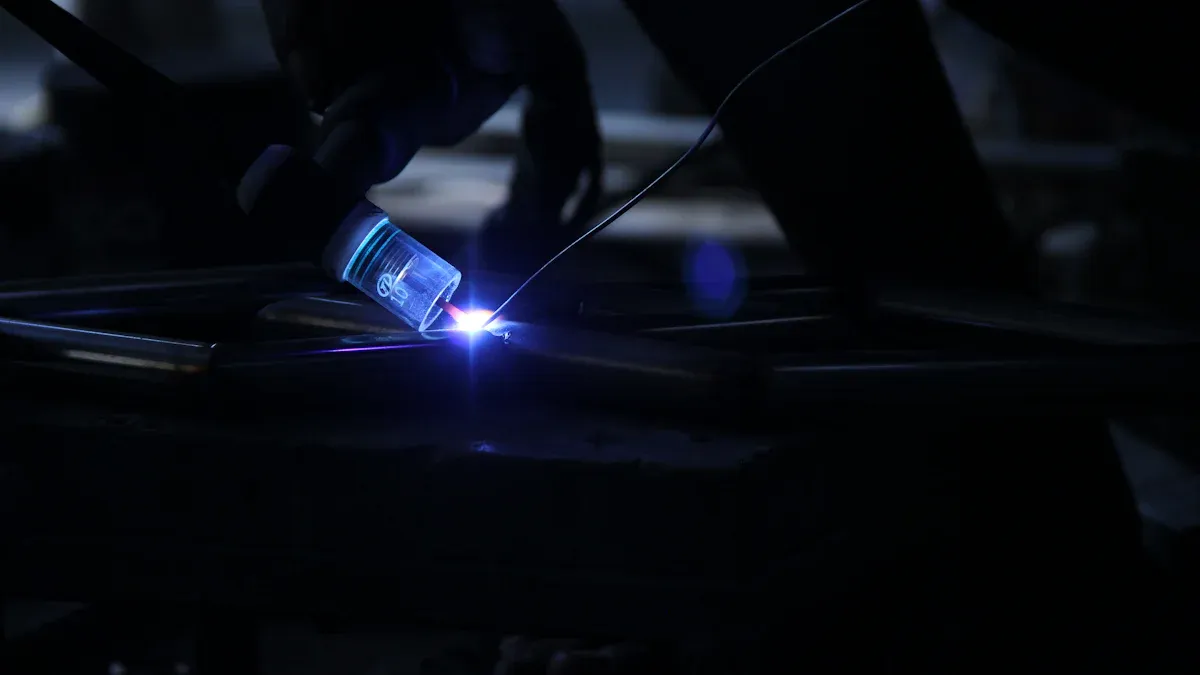

Welding titanium needs careful work and skill. The TIG welding process is the best way to weld titanium bike frames. This method has many benefits that make it great for this special metal.

TIG Welding Process

When you decide to TIG weld titanium, follow these important steps to get good results:

Preparation: First, make sure all materials, tools, and surfaces are clean. Use stainless steel brushes and tools made for titanium to keep it clean.

Cleaning: Take off the oxide layer from the titanium. You can use a grinder or a stainless steel wire brush. Then, wipe the welding area with a lint-free cloth and a strong cleaner.

Shielding Gas Setup: Use argon or a mix of argon and helium as your shielding gas. This gas protects the filler rod while you weld.

Welding Technique: Start a pre-flow of shielding gas for about 5 seconds before you begin the arc. Keep the gas flowing for 25 seconds after welding to protect the weld area.

Alignment: Use a frame alignment table to fix any bends during welding. This helps keep everything lined up correctly.

TIG welding is known for its high accuracy and control. This makes it perfect for welding titanium. You will create strong, high-quality welds with a clean look, which is important where strength and appearance are needed. This method lets you control heat and filler material carefully, lowering the chance of problems like brittleness and cracks.

Filler Rod Selection

Choosing the right filler metal is very important for strong welds. The best filler rod for welding titanium bike frames is ER Ti-5 (6AL-4V). Here’s why:

Filler Rod Type | Suitable Grades | Advantages | Additional Information |

|---|---|---|---|

ER Ti-5 (6AL-4V) | Grade 9, 5, and 2 | High fatigue strength, toughness, ductility | Suggested by Dedacciai, AWS A5.16, tensile strength 130,000 PSI, elongation 10% |

Using the right filler rod makes sure your welds have the same qualities as the base metal. This is key for the strength and performance of your bike frame. When you pick the right filler metal, you improve the overall quality of your welds.

Common Challenges in Welding Titanium

Welding titanium has special challenges, especially with heat control and keeping it clean. Knowing these problems can help you get better results when working on your titanium bike frame.

Heat Management

When you weld titanium, controlling heat is very important. Too much heat can make the material expand and shrink a lot. If you don’t manage this heat well, it can cause bending and damage to nearby areas. To stop these problems, keep your heat settings low. This helps keep the titanium strong and lowers the chance of warping.

Be careful that the temperature range where cracks happen in some titanium alloys is between 750°C and 850°C. Staying below this range can help you avoid big issues. Always watch your heat closely to make sure your weld is good.

Avoiding Contamination

Keeping things clean is another big worry when welding titanium. Airborne materials, like oxygen, can ruin your weld quality. To avoid contamination, do these things:

Check the work area, tools, and practices before starting.

Use clean tools just for titanium to avoid dirt.

Clean around the weld with stainless steel or titanium brushes and use non-chlorinated cleaners before welding.

Use an inert gas shield while welding to protect the weld metal and heat-affected zone (HAZ).

Keep an inert gas back purge for butt welds during welding until it cools below 400°C.

Using argon as your shielding gas is very important. Argon keeps the molten weld safe from air and helps keep a clean atmosphere until the piece cools. By following these steps, you can greatly lower the chance of contamination and make high-quality welds.

By focusing on heat control and avoiding contamination, you can get better at welding and create stronger, more reliable titanium bike frames.

Tips for Successful Welding

Welding titanium bike frames needs the right tools and methods. This helps you get great results. Here are some important tips to help you do well.

Equipment Recommendations

To make strong welds, buy these tools:

Specialized welding equipment: Use TIG welding machines made for titanium. They give you good control over heat and filler material.

Purging devices: These push air out of the weld area to stop contamination.

Gas shielding welding lenses: Protect your eyes and let you see the weld pool clearly.

Heat sinks: These help control heat while welding, which lowers the chance of warping.

Cleanliness tools: Keep your workspace and tools clean to keep gas pure and avoid dirt.

Using high-purity argon for TIG welding is very important. This gas keeps the weld safe from oxidation and makes a strong bond. A clean area without contaminants like CO2, O2, and moisture is key for good welding.

Best Practices for Weld Quality

Follow these best practices to make your welds better:

Two-step welding process: Treat each weld as two steps. This helps make your joints strong and consistent.

Frame alignment: Use a special alignment table to fix any misalignments while welding. This leads to better performance.

Contamination control: Fully purge the tubes with argon gas before welding. Clean the tubing well to remove dirt that can weaken your welds.

Heat control: Keep your heat settings low to avoid distortion. Steady heat is important for strong joints.

Regular inspection: Check your welds often. This helps keep them durable and fixes any problems quickly.

By using these tips and the right tools, you can greatly improve your welding skills. Learning the best way to weld titanium will help you make stronger, more reliable bike frames.

Welding titanium bike frames needs careful planning and skill. Here are the main points:

Precision alignment is very important. Always check if your frame is straight.

Start with basic parts and then move to tricky joints.

Finish welding by hand to get better access and control.

To improve your skills, look at these resources:

Online training programs

Research journals

Groups like the American Welding Society

Remember, practice is key. As Malcolm Gladwell says, it takes time to master a skill. So, keep improving your techniques and trying new ways. Your hard work will help you make stronger, more reliable titanium bike frames. Happy welding! 🚴♂️

FAQ

What is the best method for welding titanium bike frames?

The best way to weld titanium bike frames is TIG welding. This method gives you great control and accuracy. It helps make strong and clean welds.

How do I prevent contamination while welding titanium?

To stop contamination, keep your work area clean. Use tools that are only for titanium. Make sure the shielding gas flows well while you weld.

What type of filler rod should I use for titanium?

Use the ER Ti-5 (6AL-4V) filler rod for welding titanium. It works well with common titanium alloys. This helps make strong welds.

How can I manage heat during titanium welding?

Control heat by using low settings on your welding machine. Watch the temperature closely to avoid bending and cracking.

Is titanium welding expensive?

Welding titanium can cost more than other metals. This is because of the material costs and special tools needed. But the strong and lasting results often make it worth the money.

See Also

Complete Guide to Welding a Drift Trike Frame

Why Titanium Bike Frames Are Unique and Superior

Learn Simple Techniques to Draw Bike Frames Effectively